Injection Molding

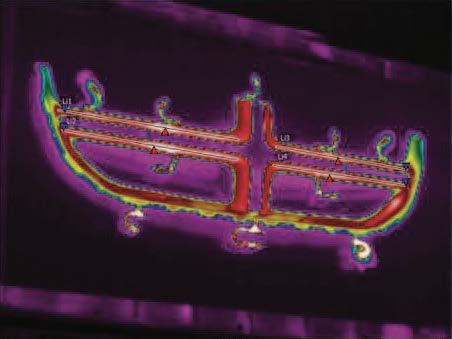

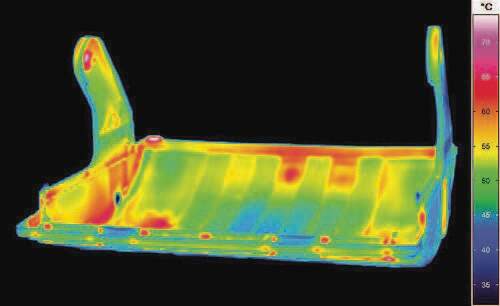

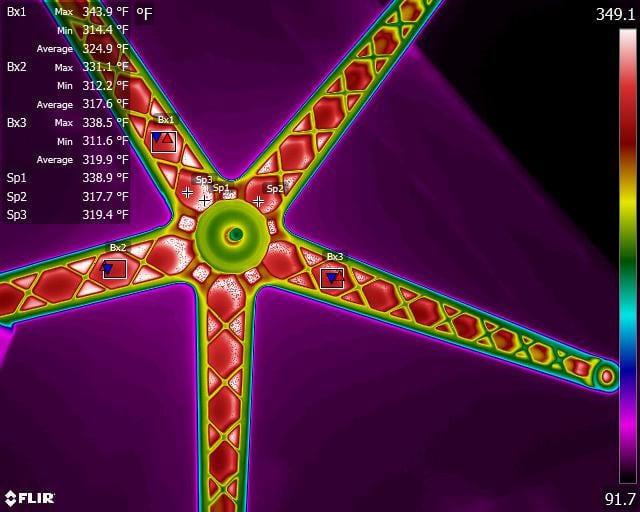

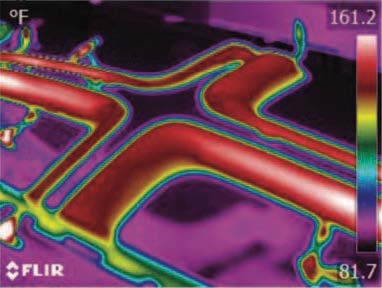

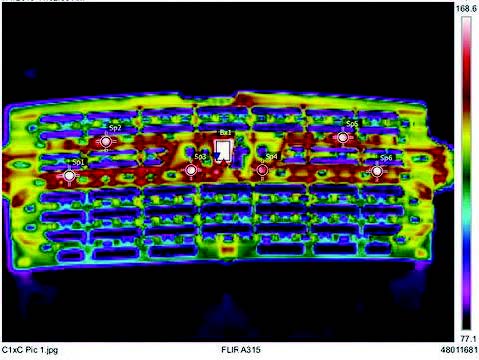

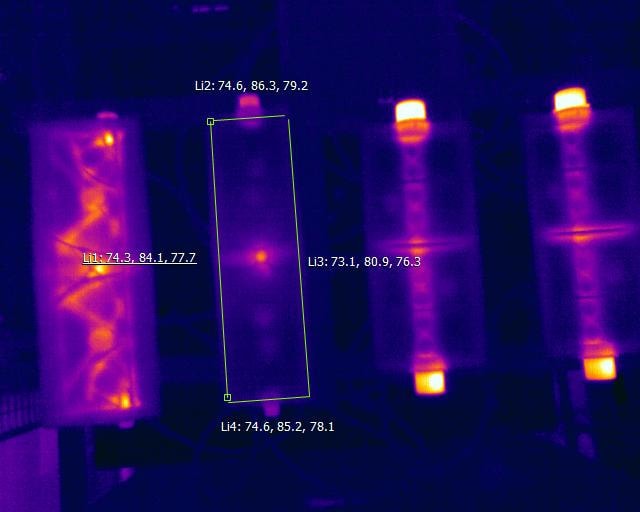

Our thermal imaging solution is the perfect tool for identifying and addressing defects in injection molding processes. With our technology, you can easily detect and diagnose issues in your injection molding processes, improving the quality and consistency of your finished products. Plus, our thermal imaging solution provides real-time feedback on the temperature distribution of your injection molding processes, allowing you to optimize and improve your techniques.

One of the key benefits of our thermal imaging solution is its ability to detect and diagnose problems in your injection molding processes before they become visible to the naked eye. This means that you can catch and fix defects early on, reducing waste and rework and improving the overall quality of your finished products. Plus, our technology is non-invasive and non-destructive, so it won’t interfere with your injection molding processes or damage your molds or products.

Another key benefit of our thermal imaging solution is its ability to provide traceability and transparency in your injection molding processes. With our technology, you can easily track and monitor the temperature distribution of your molds and finished products, allowing you to identify and address any issues quickly and efficiently. This means that you can maintain high standards of quality and consistency, and meet any traceability requirements that your industry may have.

In addition to its effectiveness and non-invasive nature, our thermal imaging solution is also incredibly efficient and cost-effective. It saves you time and money by allowing you to quickly diagnose and fix problems in your injection molding processes, reducing waste and rework. Plus, it’s easy to use, so you can quickly train your team and start seeing results right away. Overall, our thermal imaging solution is the perfect tool for anyone looking to improve the quality and reliability of their injection molding processes. Try it today and see the difference for yourself.