Quartz Infrared Emitters

Features

1. Extremely high temperature threshold, up to 932° F

2. Instant response time

3. Focused heated area relative to conductive and convective heating methods

4. Non-contact, does not disturb the product like conductive or convective heating methods

|

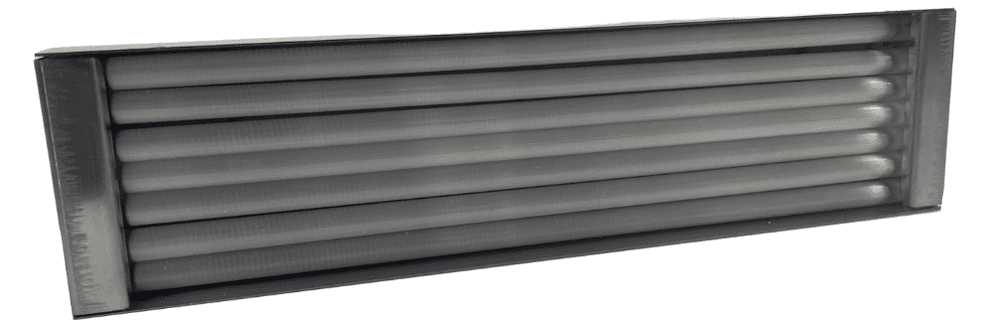

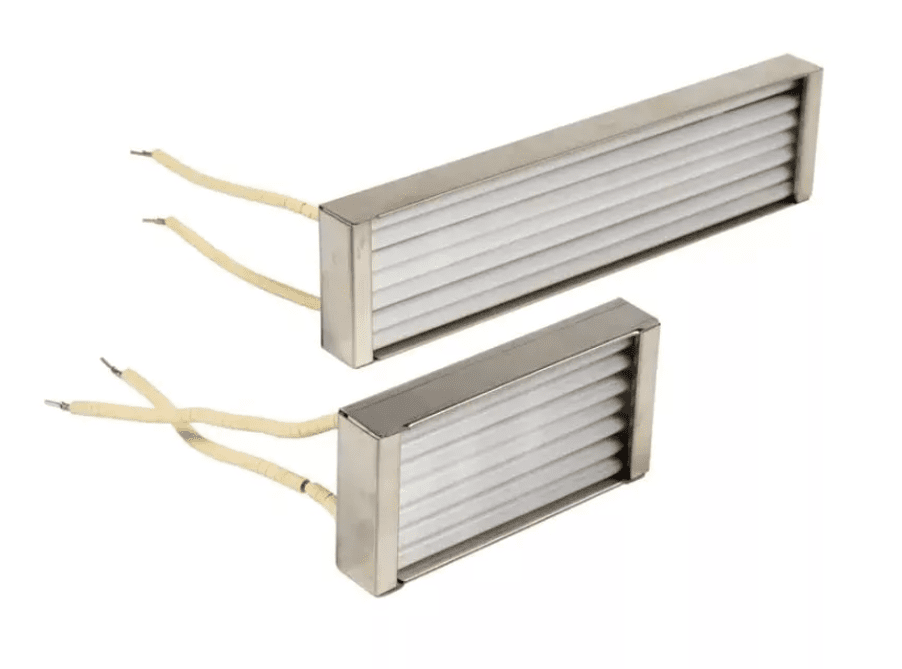

Infrared Heater Element

|

A multipurpose infrared quartz heating element (150-500W) with an instant heat response for a variety of industrial applications. This model is a great choice for processes where immediate heating is required.

|

|

Technical Information

|

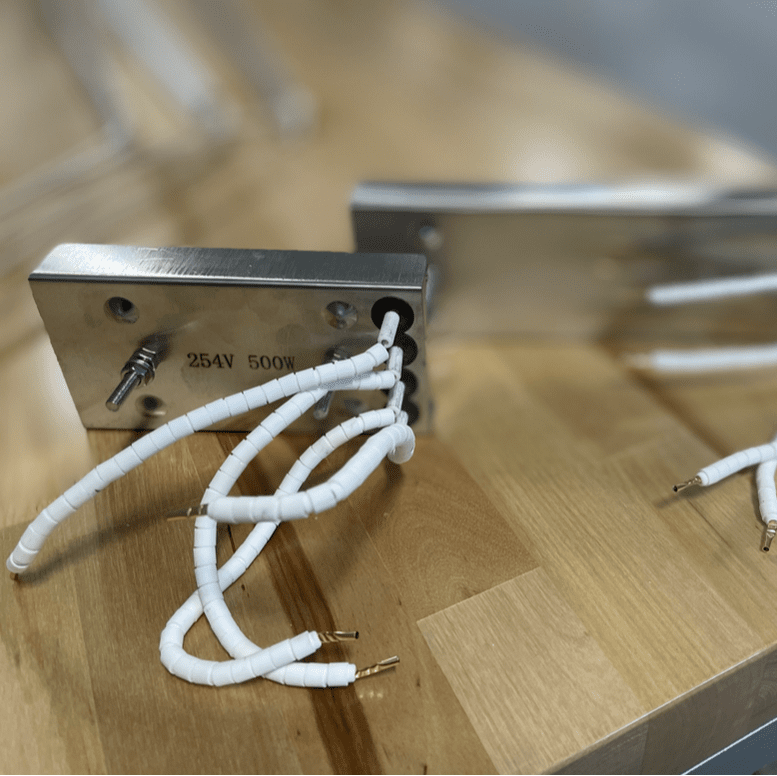

Wattage: 150 – 500 W

Measurement: 247 x 62 x 5 mm Weight: ~10.58 oz. Applicable wavelength range: 1.5 – 8 Microns Voltage: 230 V standard Operating life: 10,000, depending on conditions Contains Iron-chrome aluminum resistance wire Recommended radiation range: 4″ – 7.5″ Recommended spacing between elements: Minimum of 5 mm |

Quick response

The smaller the quartz heater, the more immediate the thermal response speed (the faster the heating rate and cooling rate) under the same power condition.

High thermal efficiency

The monolithic metal shell effectively reflects infrared rays to the front of the heater and avoids infrared “leakage” from the back because of possessing a very low absorption efficiency for infrared rays. The high-purity quartz glass tube ensures that the majority of the medium and long-wave infrared rays emitted by the resistance wire can penetrate the quartz tube and be directly used by objects.

Heating evenly

Several quartz tubes with heating wires are arranged in the Quartz tube, radiating infrared rays in the form of a surface during operation. In contrast to the omnidirectional emission of the single-tube heater, the temperature consistency when heating the quartz heater is higher, and the infrared energy at each point on the surface of the receiving material will complement each other, effectively avoiding all uneven heating.