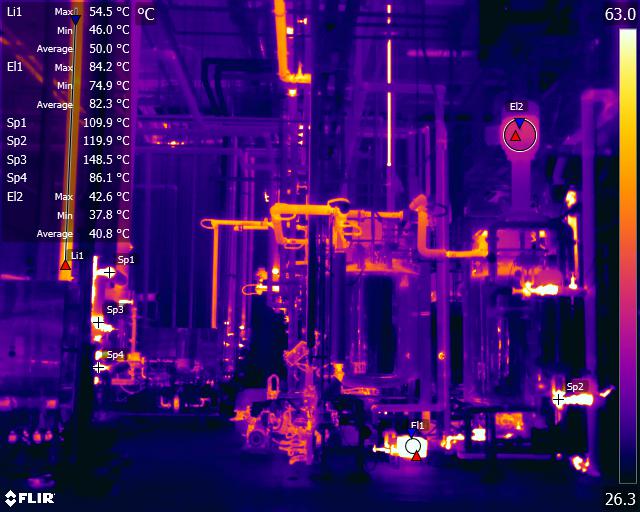

Real-Time Condition Monitoring to Prevent Equipment Failures

Predict problems before they happen with thermal insights that extend asset life and reduce downtime.

In critical industrial environments, unexpected equipment failures can lead to costly delays and safety risks. Emitted Energy’s condition monitoring solutions use infrared technology to continuously track temperature changes—enabling predictive maintenance and operational efficiency.

Unplanned Downtime Costs More Than You Think

Manual inspections and reactive maintenance often lead to late interventions, system inefficiencies, and unexpected breakdowns that impact productivity.

- Inability to detect early-stage equipment failures

- Reliance on scheduled maintenance, not actual conditions

- High repair and replacement costs

- Safety hazards from undetected overheating or wear

How Our Solution Solves These Issues

- Detect abnormal heat signatures early

- Enable predictive, not just preventive, maintenance

- Reduce operational disruptions and repair costs

- Monitor inaccessible or hazardous equipment safely

Condition Monitoring Solutions by Emitted Energy Corporation

See the Signs Before They Become Shutdowns

Start using thermal monitoring to protect your equipment, people, and profits—connect with our team today.

Trusted by Businesses Worldwide

Don’t Wait for Equipment to Fail

Schedule a call with our experts to explore how Emitted Energy’s condition monitoring can reduce risk, save costs, and enhance safety.