Infrared Accuracy for Superior Packaging and Sealing

Ensure consistent seal integrity and reduce waste with precision thermal monitoring and control.

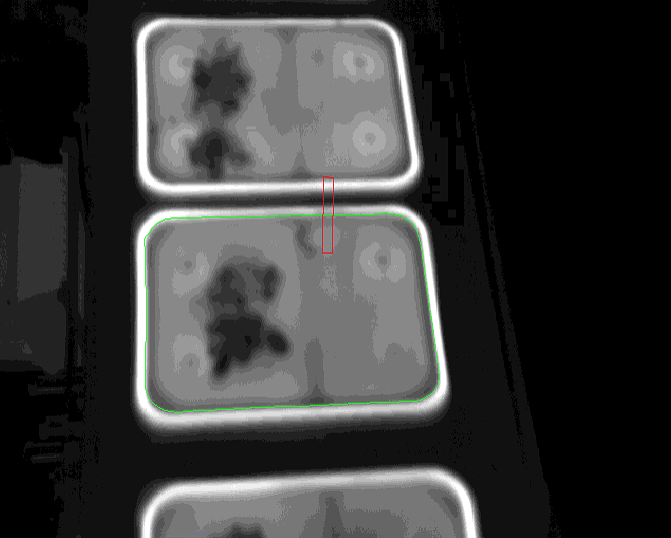

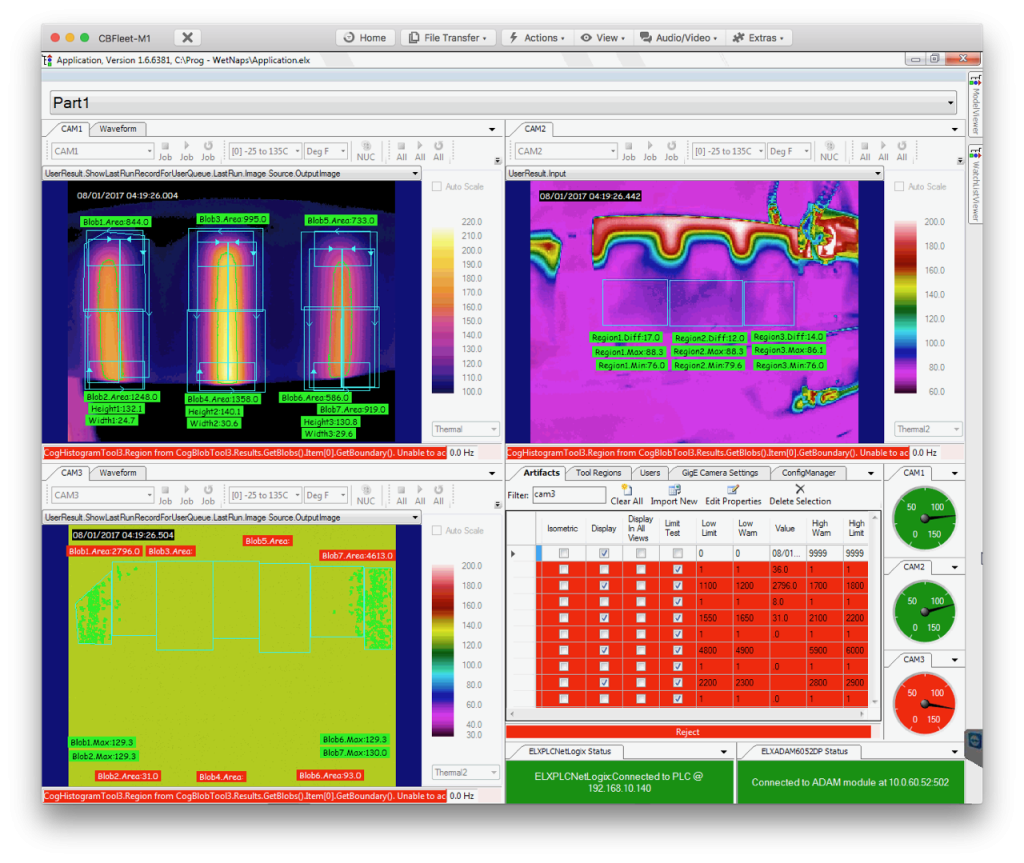

In packaging and sealing, precision matters more than ever. Faulty seals can lead to contamination, spoilage, and costly recalls. Our infrared systems provide real-time, non-contact thermal analysis to detect inconsistencies before they become problems. Whether you’re sealing food, pharmaceuticals, or consumer goods, our solutions ensure every package is sealed with confidence and accuracy.

Eliminate Packaging Inconsistencies and Seal Failures

Traditional packaging lines struggle with thermal variability, poor sealing pressure, and misalignment—leading to costly product recalls and reduced consumer trust.

- Uneven heat distribution causing seal gaps or burns

- Inconsistent dwell time and sealing pressure

- Difficulty detecting faulty seals in real time

- Increased waste from defective packages

How Our Solution Solves These Issues

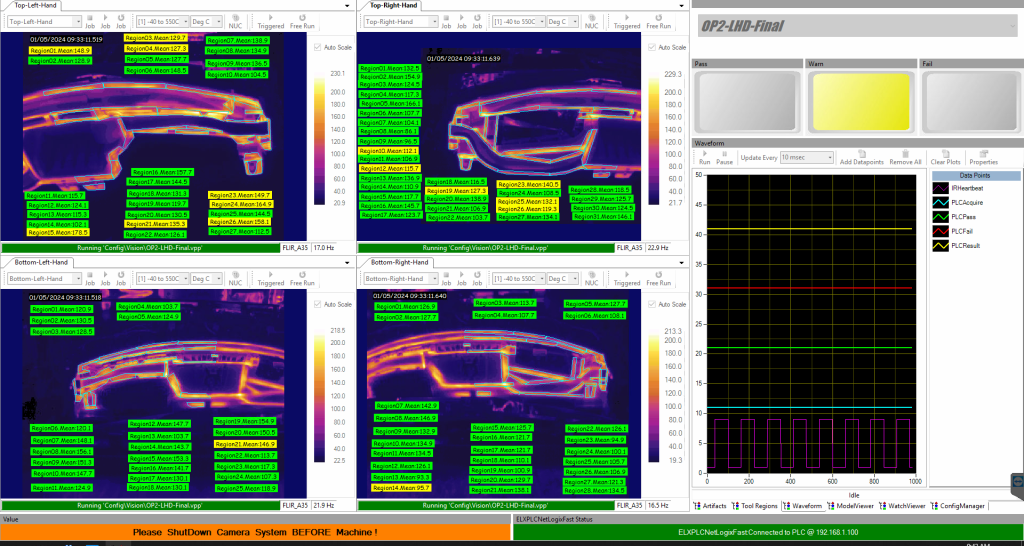

- Real-time seal validation for maximum uptime

- Reduce seal failure through optimized thermal zones

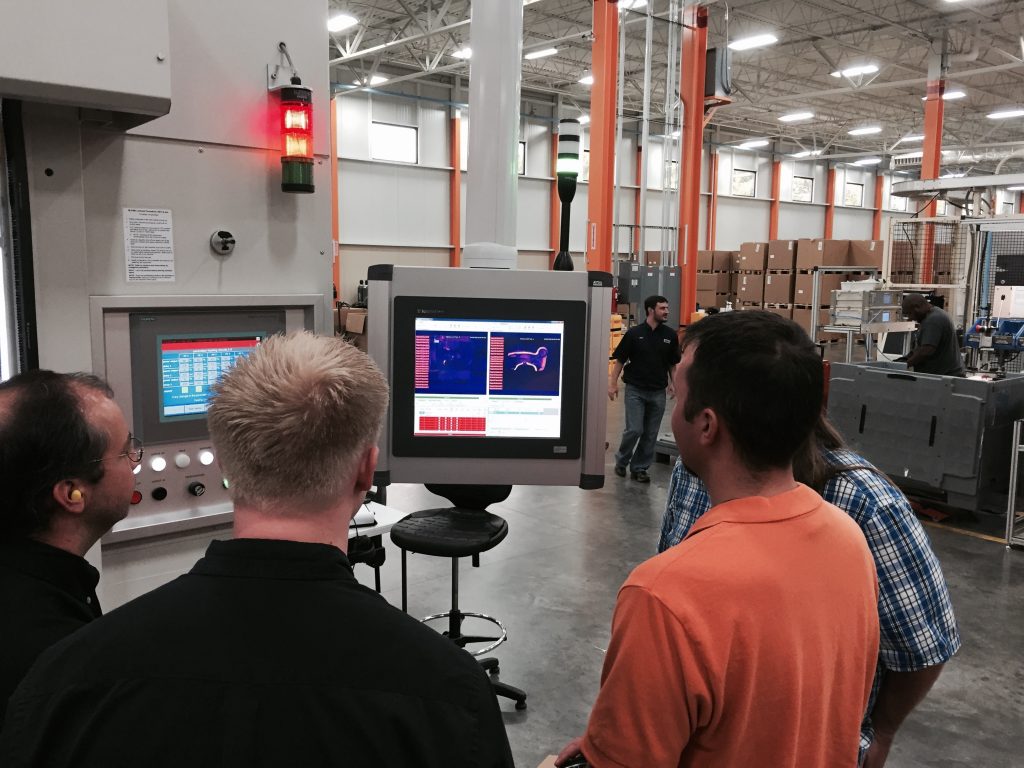

- Easily retrofit into existing packaging lines

- Meet safety standards with automated process documentation

Packaging and Sealing Solutions by Emitted Energy Corporation

Project Payback Period

Let’s Seal the Deal on Performance

Explore how Emitted Energy can transform your packaging line with smarter, more efficient thermal solutions.

See it in action

Trusted by Businesses Worldwide

Protect Every Product with Thermal Precision

Let us help you improve packaging performance with intelligent thermal monitoring that ensures consistent, high-quality results.