Infrared Heating

High-performance infrared heating technology engineered for precision heat control and consistent thermal performance.

Emitted Energy’s Infrared Emitters are crafted to deliver targeted, consistent heat for demanding industrial processes. Designed for reliability, precision, and longevity, our emitters support a wide range of thermal applications—helping you improve productivity and ensure quality from the core.

Process Heating Solutions

Our process heating solutions are engineered for maximum performance, efficiency, and control. With customizable designs, advanced monitoring systems, and precision temperature management, we provide the flexibility to meet the exact requirements of your production environment.

Built around energy efficiency, reliability, and scalability, our heating technologies help manufacturers reduce operating costs while ensuring consistent product quality. Real-time monitoring and intelligent controls offer greater insight into system performance, enabling optimized processes and predictive maintenance.

Whether you need a fully tailored system or modular solutions that grow with your operation, our process heating technology delivers long-term value through enhanced productivity, lower energy consumption, and superior reliability.

Infrared Emitters

Infrared emitters are a powerful, energy-efficient solution for industrial heating applications. Available in short-wave and medium-wave options, they deliver fast, reliable, and targeted heat for a variety of manufacturing processes.

Short-wave infrared emitters provide intense, penetrating heat with rapid response times, making them ideal for high-speed plastic joining, thin gauge forming, and more broadly drying, curing, and finishing lines.

Medium-wave infrared emitters deliver controlled, surface-focused heating that’s perfectly suited for thermoforming plastics, coating applications, and material processing.

By choosing the right wavelength, manufacturers can improve process efficiency, enhance product quality, and reduce energy consumption. Whatever your heating application, infrared heating technology offers consistent performance and long-lasting reliability.

Ready to Upgrade Your Heating Technology?

Whether you’re improving an existing system or starting from scratch, we’ll help you implement the best-fit IR emitter solution.

What is Infrared Technology?

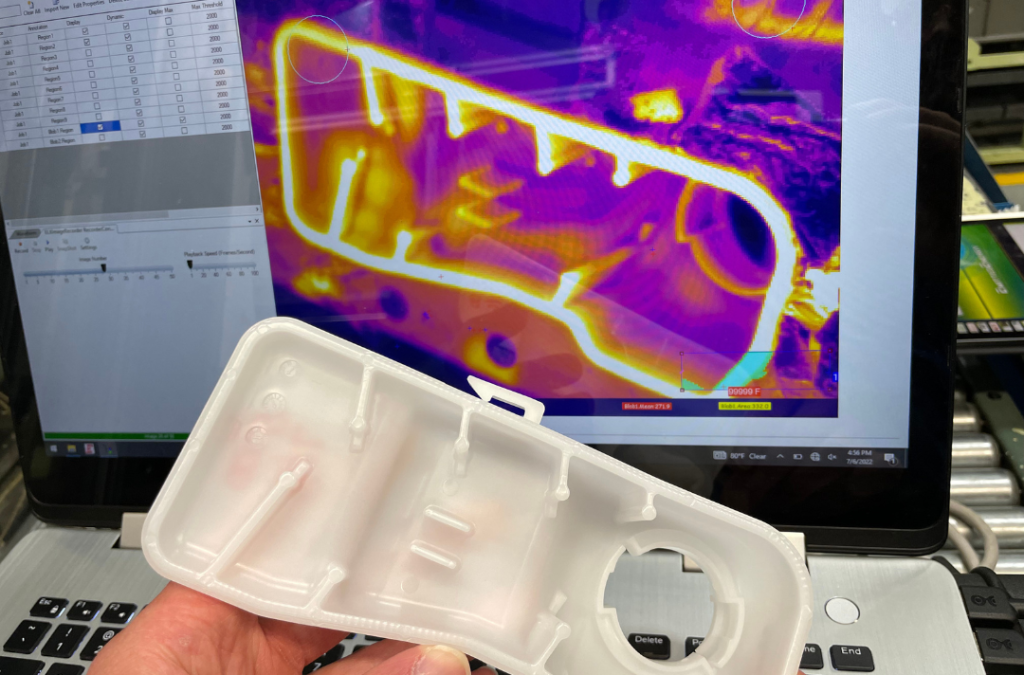

Infrared radiation is a form of electromagnetic energy emitted by atoms and molecules in all objects with temperatures above absolute zero (-273°C). Infrared (“below” or “beyond” red) lies between the visible and microwave spectrum. When infrared waves encounter an object, they can reflect, diffract, refract, transmit, or be absorbed, often simultaneously. Invisible to humans, infrared starts at 0.76 microns, extending to 10.0 microns. All objects emit infrared energy based on their temperature..

Variety of Wavelengths

We offer a broad range of infrared emitters, including:

Short-Wave Emitters

Ideal for applications requiring intense heat and immediate response.

Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

Filament Material: Tungsten

Filament Temperature: 1800 – 2400°C (3300 – 4400°F)

Peak Wavelength: 1.0 – 1.4 µm

Response Time: About 1 sec.

Typical Applications:

- Plastics Welding

- Curing Painted Surfaces

- Curing Powder Coatings

- Polymerization of coatings for cooking utensils

- Drying porcelain and ceramics

- Drying and production of glass-plastic composites

- Semiconductor Production

Fast-Response Medium-Wave Emitters

Suitable for processes needing rapid temperature adjustments.

Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

Filament Material: Tungsten

Filament Temperature: 1400 – 1800°C (2500 – 3300°F)

Peak Wavelength: 1.4 – 1.6 µm

Response Time: 1 – 2 sec.

Typical Applications:

- Drying Processes

- Plastics Processing

- Curing of Coated Surfaces

- Gelling PVC coatings on textiles

- And Many Others…

Carbon-Based Medium-Wave Emitters

Perfect for applications that require precise thermal profiles.

Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

Filament Material: Wound Carbon Fiber-Woven

Filament Temperature: ~ 1200°C (~ 2200°F)

Peak Wavelength: ~ 2.0 µm

Response Time: > 3 sec.

Typical Applications:

- Drying Processes

- Curing of Coated Surfaces

- Pre-heating and Post-heating

- And Many Others…

Medium-Wave Emitters

Versatile solutions for various industrial heating needs.

Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

Filament Material: Nickel-Chromium Alloy

Filament Temperature: 800 – 950°C (1500 – 1800°F)

Peak Wavelength: 2.0 – 4.0 µm

Response Time: > 1 min.

Typical Applications:

- Curing Painted Surfaces

- Preheating Plastics

- Curing Powder Coatings

- Drying / heat setting textiles after dyeing or printing

- Supplemental heating

- Drying or inks for printing and silk-screening

- Preheating and curing wood coatings

- Glass Curing

- And Many Others

Efficient Heating

Our infrared emitters deliver efficient heating, enhancing product quality and operational efficiency across diverse industries.

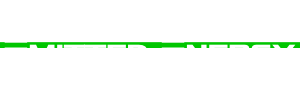

Integration with Thermal Cameras

When integrated with our advanced thermal cameras, these emitters facilitate Infrared Machine Vision, Process Control, and Quality Assurance Imaging. This combination helps identify inefficiencies and thermal anomalies, ensuring optimal process performance.

Heater Banks

Emitted Energy Corporation also provides heater banks, offering a cost-effective solution for incorporating infrared heat into industrial processes. These banks simplify the adoption of infrared technology, improving efficiency and product quality.

Precision and Control

Our emitters are engineered for precision and control, which are essential for maintaining high standards of product quality and operational efficiency.

Integration with PLCs

When coupled with phase-angle power controllers, the emitter can be controlled directly through a PLC and seamlessly integrated into a heating process, enabling automated power adjustments, optimal temperature control, and process efficiency.

Real-Time Monitoring

Leveraging thermal imaging technology to enable real-time monitoring and tracking of temperature changes. This provides valuable data-driven insights into process control, performance, and optimization.

We supply.

We support. We partner on solutions.

Project Payback Period

Trusted by Businesses Worldwide

Elevate Your Thermal Application with Our Infrared Emitters

Experience unmatched control and reliability with Emitted Energy’s engineered IR emitters. Let’s help you design the ideal heating solution.