Seal and Adhesive Solutions

How Thermal Imaging Solutions Help Manufacturers with Adhesive Validation

Thermal imaging solutions are increasingly becoming a must-have for manufacturers utilizing an adhesive validation process. This technology is invaluable in ensuring that adhesives are applied correctly and consistently throughout manufacturing.

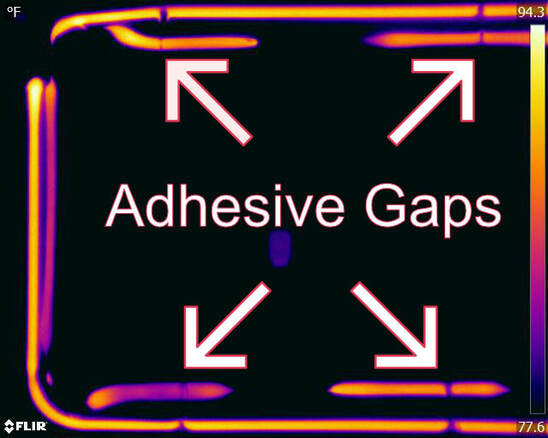

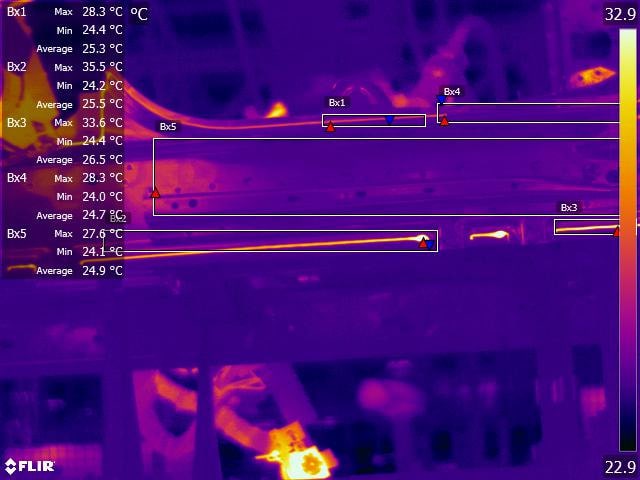

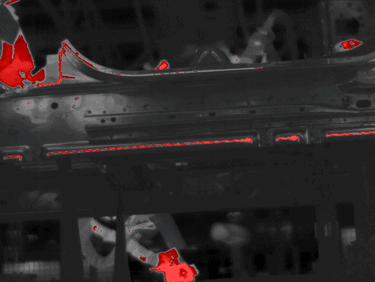

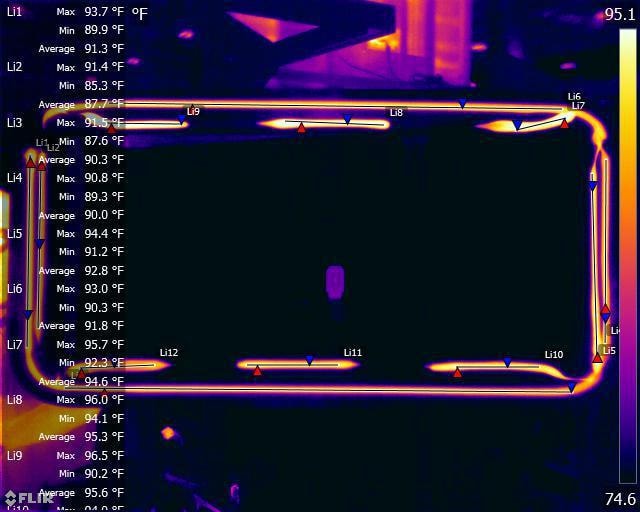

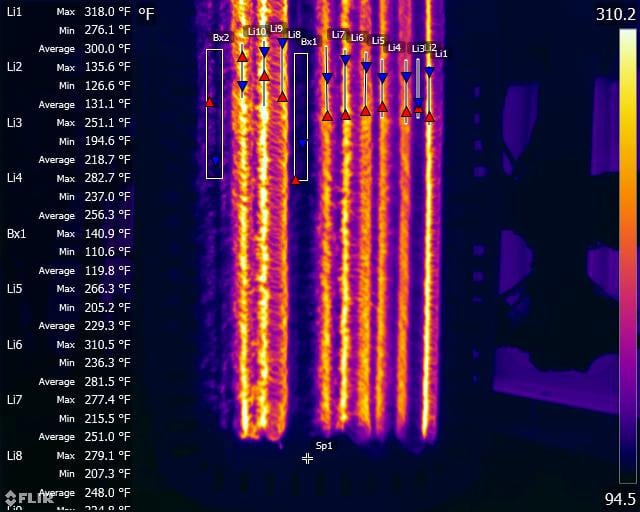

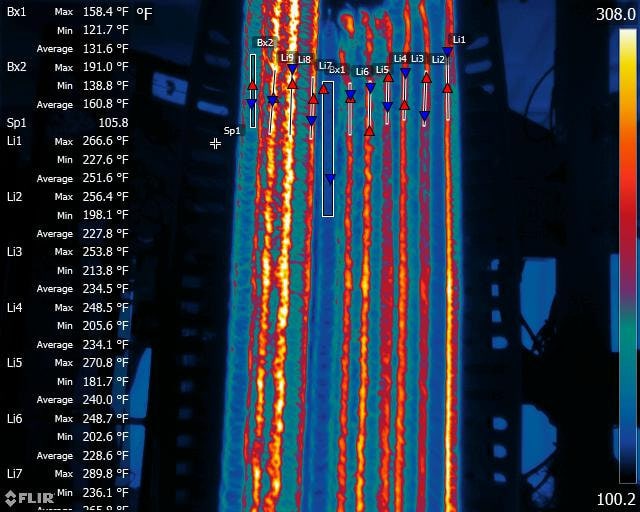

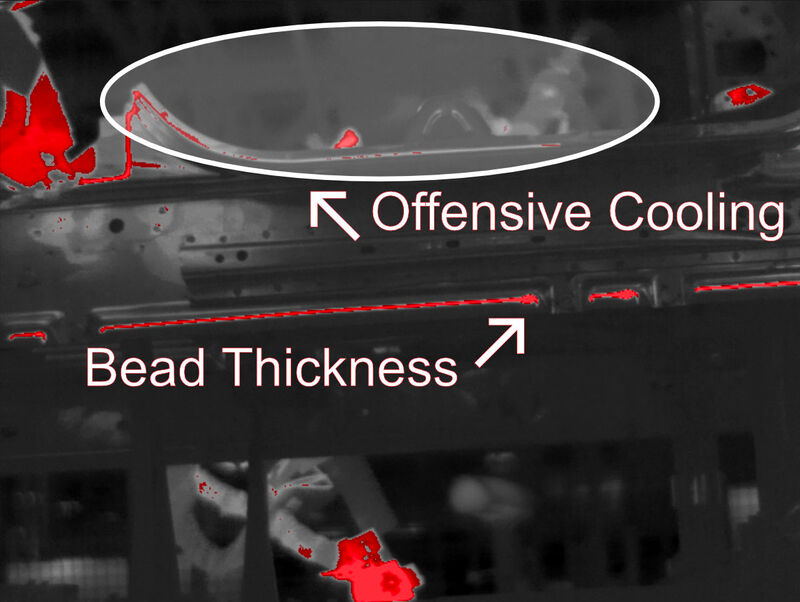

With thermal imaging, manufacturers can more easily detect temperature variances during application and validate if their adhesive requirements are being met. The temperature is usually secondary to the inspection which focuses on gap and light application detection.

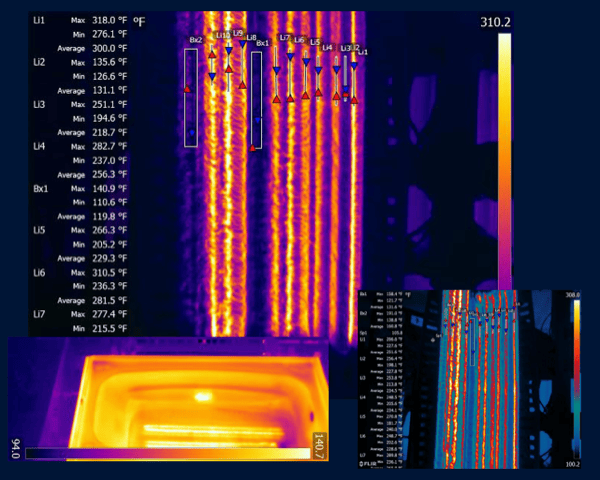

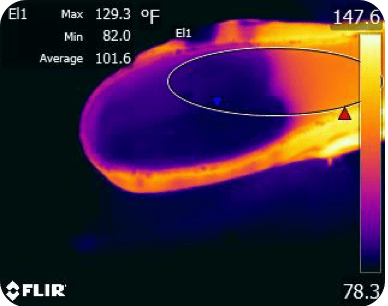

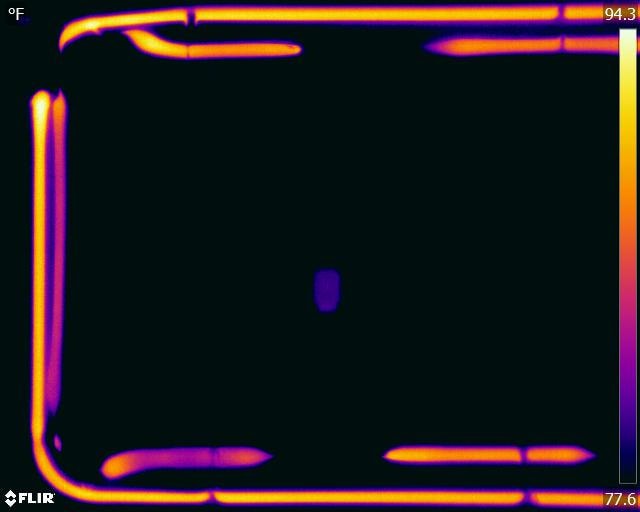

Thermal images offer highly detailed images of the temperature distribution on the surface. This data can be used to quickly detect hot spots or cold spots that might indicate substandard performance. In addition, thermal imaging helps ensure that all surfaces that require quality adhesive application have the adhesive correctly dispensed and at the right temperature.

Temperature is a key factor in ensuring that adhesives will bond correctly – if the surface is too hot or too cold, it can negatively affect the strength of the bond and even cause it to fail altogether. By utilizing thermal imaging technology, manufacturers can be sure that all surfaces are at the proper temperatures for successful adhesive bonding.

Benefits of Using Thermal Imaging for Bonding Two Materials Adhesively

Thermal imaging for adhesively bonding two materials offers many benefits beyond traditional methods of joining materials. Here are five reasons why thermal imaging is an excellent choice for adhesive bonding:

- Ease of Use: It can be used quickly and easily, allowing operators to monitor temperatures in real time without any complicated setup or calibration procedures. This makes it an ideal solution for applications that require frequent temperature changes. This would be all after the initial setup and this setup can be complex so ease of use would be something to look forward to after the setup is complete.

- Enhanced Quality: It provides highly accurate temperature readings, so it’s easier for adhesive applications at just the right temperature for optimal bond strength and performance. Gap/sputter detection will also ensure that proper bond fills and not voids are left behind in the process.

- Time Savings: It saves time on the bonding process, by eliminating the need for destructive testing and easily identifying or eliminating the need for rework. This saves time in production and will enable manufacturers to improve their overall efficiency and output quality.

- Cost-effective: It can save money by eliminating costly rework due to faulty adhesion caused by incorrect temperatures or other problems. Integrated thermal process monitoring also reduces energy consumption, thereby helping reduce operational costs. Nondestructive testing (NDT) is a cost-effective measure that can help identify issues with adhesion prior to final assembly.

Most Reliable Thermal Imaging for Adhesive Validation At Emitted Energy Corporation

With the rapid changes in today’s manufacturing industry, accurate adhesive validation and quality control are more important than ever. Thermal imaging solutions have become indispensable within manufacturers to provide data-driven insights into the validity of an adhesive, given varying conditions and factors.

Emitted Energy Corporation has revolutionized this technology and set the industry standard for adhesive application solutions. From verifying whether a sealant has been appropriately applied to answering complex questions about comparing two adhesives, Emitted Energy Corporation redefines how manufacturers approach adhesive validation. Contact us today for efficient, reliable, and quality-controlled results to guarantee customer satisfaction each time!