Blow Molding

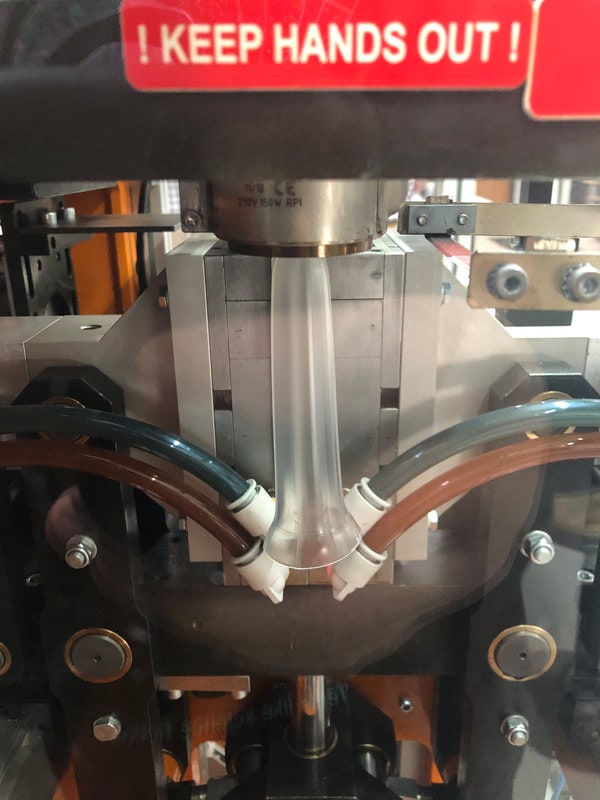

The key component to a consistent and controllable blow-molded part is the quality of the parison produced from shot to shot. This is a challenge since, unlike other plastic processing systems, blow molding is the only process that has the material open to the environment and its influences. Along with the production of poor quality parisons, with thin spots and uneven heating throughout the circumference of the parison, this environmental factor influences part quality and consistency along with all of the other machine and system related variables.

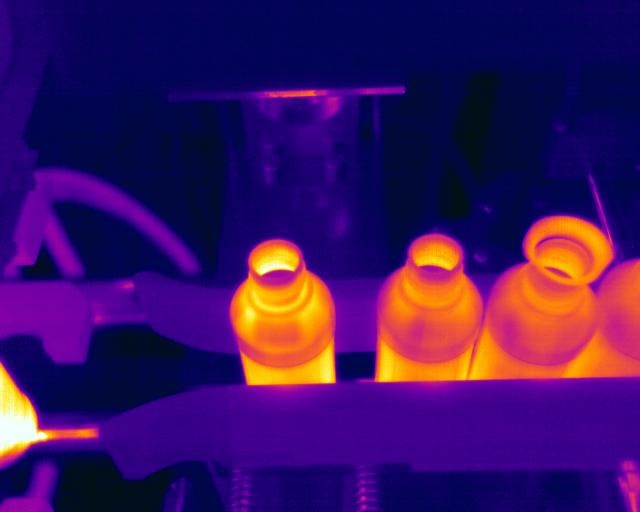

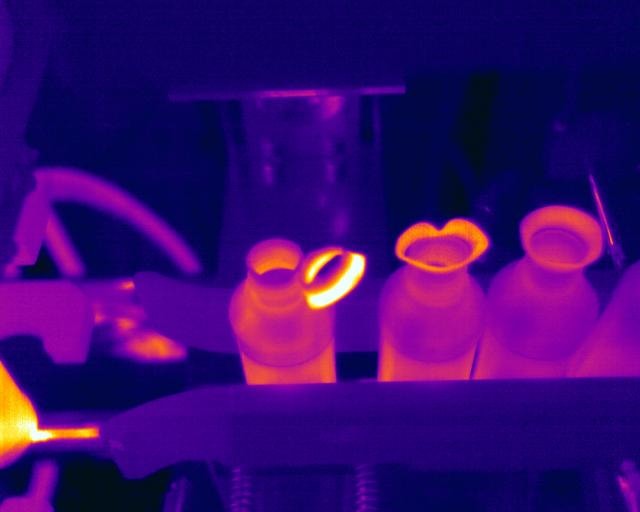

Up to now the industry has not been able to monitor the most important element in the blow molding process, the parison itself. Monitoring this area coupled with understanding the ambient temperature of the interior of the tool is the key to any blow-molders success.

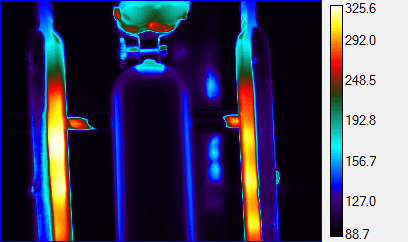

Now with Emitted Energy’s Thermal Process Monitoring system utilizing Teledyne FLIR Infrared (IR) Cameras, blow molders with all types of equipment can monitor parison temperature with precision 100% of the time. This information can be used with SPC/SQC systems to provide excellent quality control. In addition to the predictive capabilities of IR monitoring, we are now able to adjust to the optimum parison temperature for part quality, consistency and part weight. All of this information can be gathered and processed into instant reporting systems and even closed-loop process control.

This is only one area where IR technology is used because we can now monitor and QC 100% of all finished blow molded parts for the most minute of changes from specifications. We can monitor surface temperatures for Molds, Head Tooling, Heater Banks and even electrical components, hydraulic pumps and electric motors to even predict potential problems.

Thermal imaging solutions can be an effective tool for monitoring and improving blow molding processes. These solutions use specialized cameras to capture infrared radiation emitted by the materials and equipment used in blow molding, providing a visual representation of the temperature distribution within the process. This can help manufacturers identify potential problems, such as uneven heating or cooling, and make adjustments to improve the quality and consistency of their products.

One key benefit of using thermal imaging solutions for blow molding is their ability to provide real-time temperature data. This allows manufacturers to monitor the process continuously and make adjustments on the fly, reducing the risk of defects and improving the overall efficiency of the operation. Additionally, thermal imaging solutions are non-invasive and do not require any physical contact with the materials or equipment, making them a safe and easy-to-use tool for monitoring blow molding processes.

Another advantage of thermal imaging solutions is their ability to help manufacturers optimize the blow molding process by identifying areas where heat is being lost or wasted. This can help manufacturers save energy and reduce costs, while also improving the quality of their products. For example, thermal imaging can help manufacturers identify areas where the blow molding process is not evenly heating the material, leading to uneven thickness or other defects. By making adjustments to the process, manufacturers can improve the consistency and quality of their products.

Overall, thermal imaging solutions can be a valuable tool for manufacturers using blow molding processes. These solutions provide real-time temperature data, allowing manufacturers to monitor and adjust the process to improve the quality and consistency of their products. Additionally, thermal imaging solutions can help manufacturers save energy and reduce costs, making them an effective way to improve the efficiency and effectiveness of blow molding operations.

Demonstration Video

Testimonials

“Thermal Imaging may be used to control blow molding process by monitoring plastic melt temperature and ambient temperature.

If ambient temperature increase, plastic melt will not cool fast enough, parison will stretch, and length will increase. In this case, parison wall thickness profile will not be adequate, and will be thin and thick area in the wall of final product. Same will happen if ambient temperature become too low. In that situation, parison will get shorter, and parison wall thickness profile will not be adequate again. Wall thickness of final product will increase. If parison become too short, it could not be pinched on the bottom, it will be cut off and drop in the mold cavity. Controlling ambient and plastic melt temperature, parison length would be controlled (as much as possible), parison wall thickness profile would be “accurate” (as much as possible), result will be desired wall thickness in final product.” -Dragan Grujic (Plastivaloire America)