Thermoforming Solutions

Emitted Energy is a leading thermal imaging equipment and camera supplier for diverse applications and manufacturing procedures, such as thermoforming. The goal is to produce superior-quality plastic products through thermoforming with the help of thermal imaging equipment so that thermoforming companies can prevent premature failure that may cause expensive recalls or safety hazards in their workplace.

What is Thermoforming?

Thermoforming is a plastic manufacturing method where a plastic sheet is heated until it reaches the right temperature. The heated plastic sheet becomes pliable, allowing manufacturers to form it. Force is used to stretch the sheet of heated thermoplastic material and then apply it to a mold. It’s commonly used to create various products, such as packaging materials, interior automobile parts, and even sterile and single-use medical items.

Products manufactured through thermoforming must meet industrial quality standards to prevent customer dissatisfaction and significant losses. Due to these problems, thermoforming companies employ thermal imaging equipment to provide an effective solution to monitor the temperature during the thermoforming procedure.

How Can Thermal Imaging Equipment Help in the Thermoforming Process?

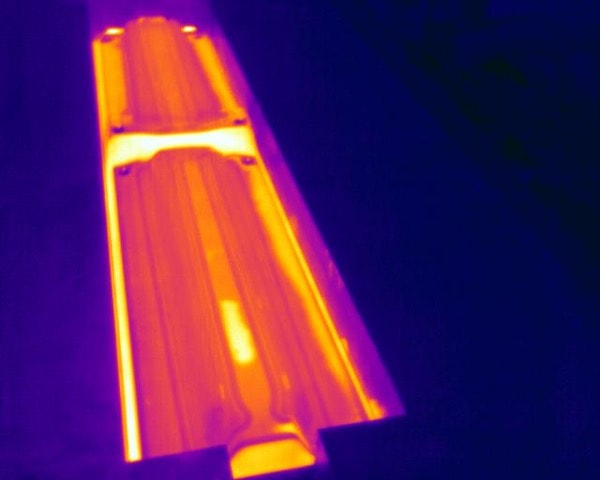

During thermoforming, where precise temperature control is essential for producing high-quality plastic products, thermal imaging cameras play a crucial role in reducing costs and ensuring product integrity. Thermal imaging technology is a valuable tool in manufacturing, providing accurate and non-intrusive methods for continuously checking temperatures and identifying potential imperfections in diverse materials, such as plastic.

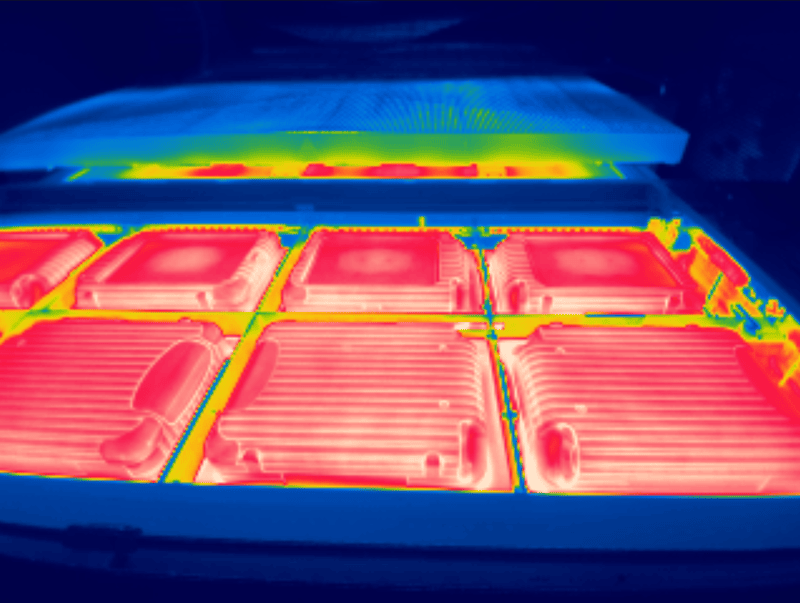

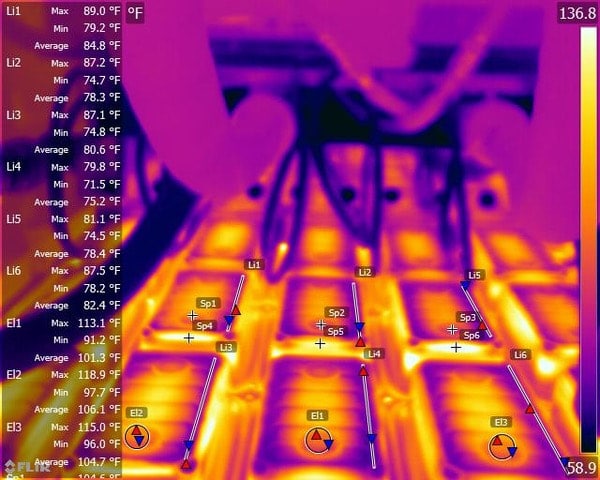

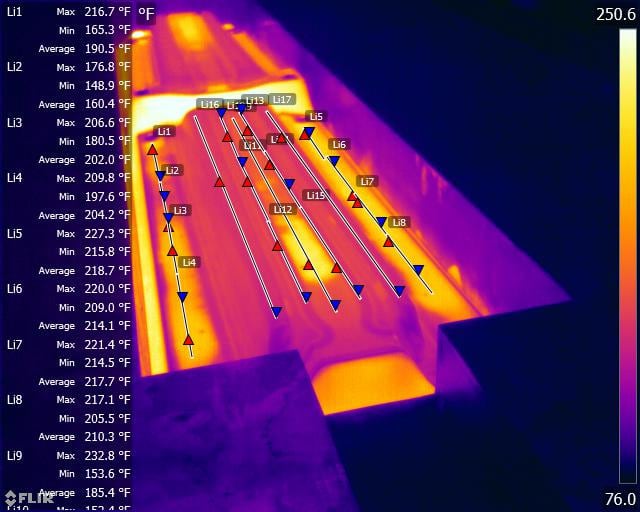

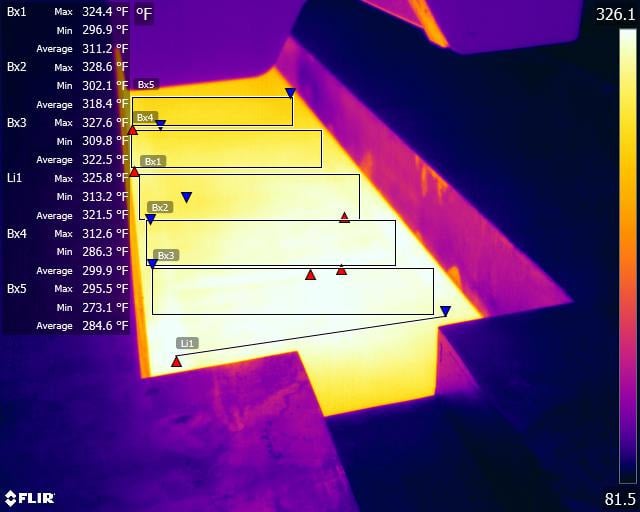

The equipment works by monitoring the temperature of the plastic sheet while it’s heated, allowing manufacturers to determine the appropriate temperature of a specific thermoplastic material for forming. It also helps pinpoint any hot or cold spots. By detecting these issues early on, manufacturers can make necessary adjustments to enhance the quality of their products.

Advantages of Using Thermal Imaging Equipment in Thermoforming

There are numerous advantages to using thermal imaging equipment during the thermoforming procedure. It can elevate your bottom line and drive profits to your business due to consistent quality outcomes.

These benefits include:

- Accurate temperature monitoring: With thermal imaging cameras, manufacturers can check the temperature of the plastic sheet in real-time.

- Resolve issues quickly: Problems are noted and identified immediately.

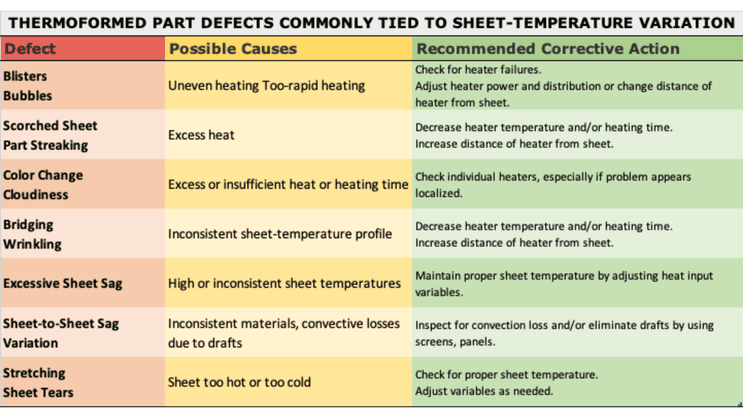

- Improve product quality: Optimizing products through efficient temperature control. Quickly identify process variability leading to Blister or Bubbles, Poor Detail in the Formed Part, Scorched Sheet, Blushing or Discoloration.

- Optimized thermoforming procedures: Creates a closed-loop system that adjusts the thermoforming process based on thermal data collected from the thermal cameras.

- Lessen product waste: Consistently accurate temperatures can effectively avoid errors and costly material waste.

- Increased productivity: Boosts efficiency and productivity by reducing the number of rejected products.

- Substantial savings: Reduces labor costs and saves time as operators can easily monitor temperature using thermal imaging cameras instead of blindly adjusting process parameters.

Trust Premier Thermal Imaging Equipment from Emitted Energy

Regardless of the complexity of your thermoforming process, Emitted Energy can provide thermal imaging equipment that will meet your needs. Our industry-leading cameras offer high-resolution images with exact measurements, ensuring the utmost accuracy and reliability in monitoring your plastic sheet’s temperature.

If you want to learn more about our services, feel free to contact us today. We’ll kick-start your journey towards more efficient and profitable thermoforming projects with high-performance thermal imaging products!