Condition Monitoring

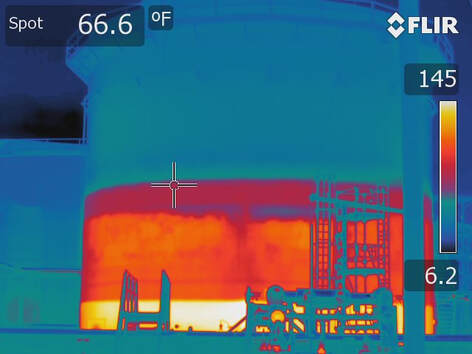

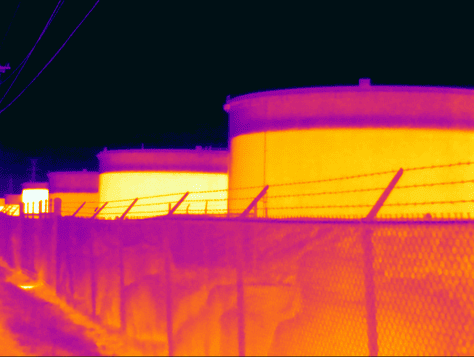

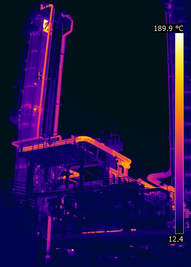

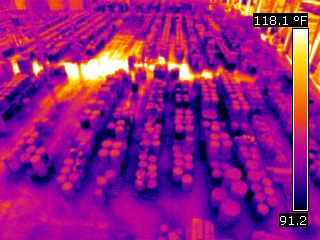

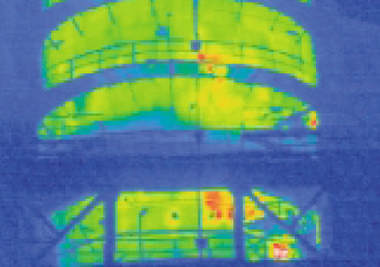

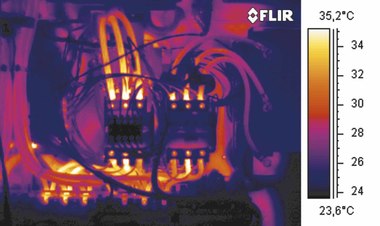

Prevent Expensive Production Stops and Facility Downtime caused by mechanical and electrical equipment failure. These types of problems used to be hard to identify proactively, but not any more. Preventing these costly stops in production can be done with thermal imaging. Our condition monitoring solution offers 24/7 Monitoring so you can sleep easy at night knowing your facility is running smoothly. Automated Alarming features make pertinent personnel aware of concerns the moment they arise, allowing you to decrease response times and prioritize pressing concerns. With features like alarm-to-email, alarm-t0-SMS, and more alongside traditional alarming capabilities including visual and audio alarming, you never have to worry again. Don’t settle for scheduled inspections, protect your company with best-in-class solutions like TPMS for Condition Monitoring.

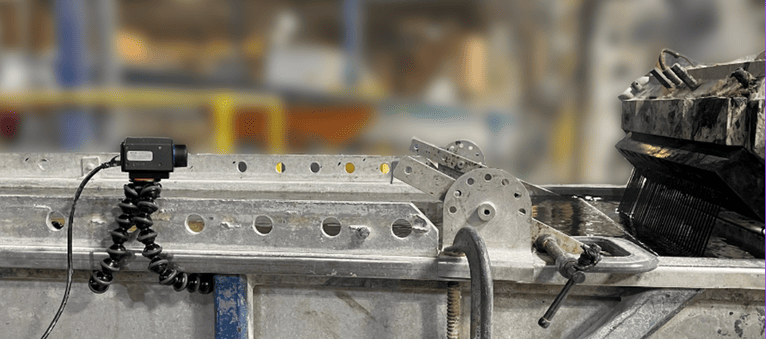

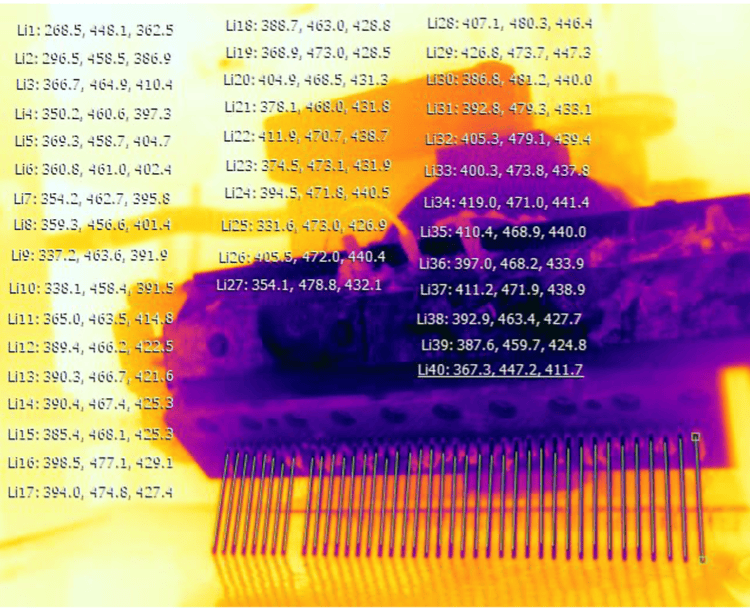

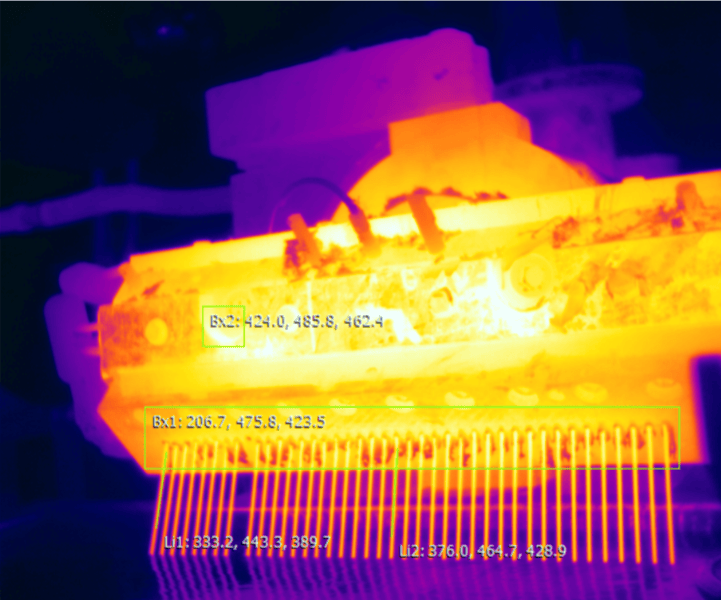

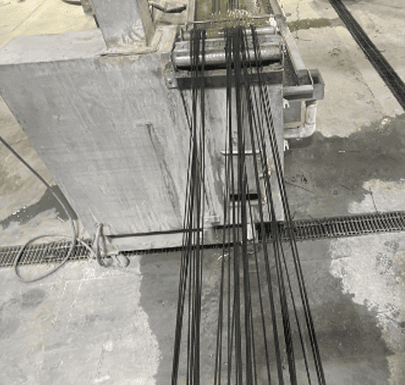

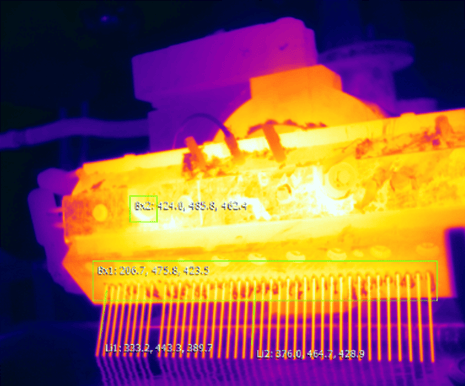

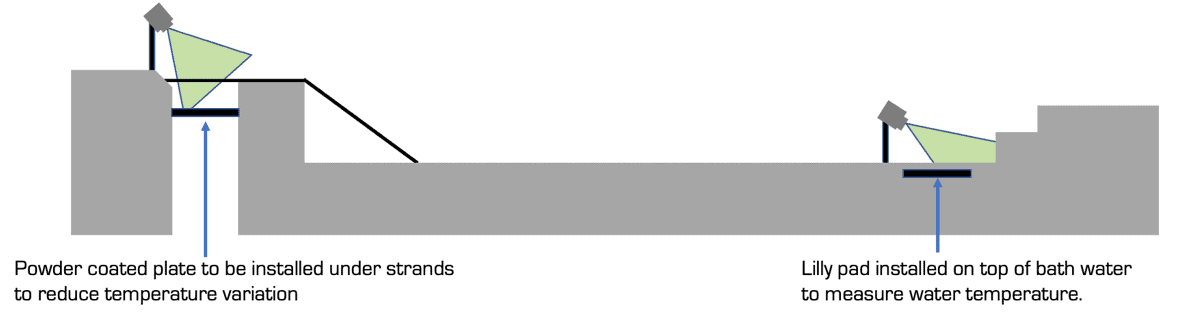

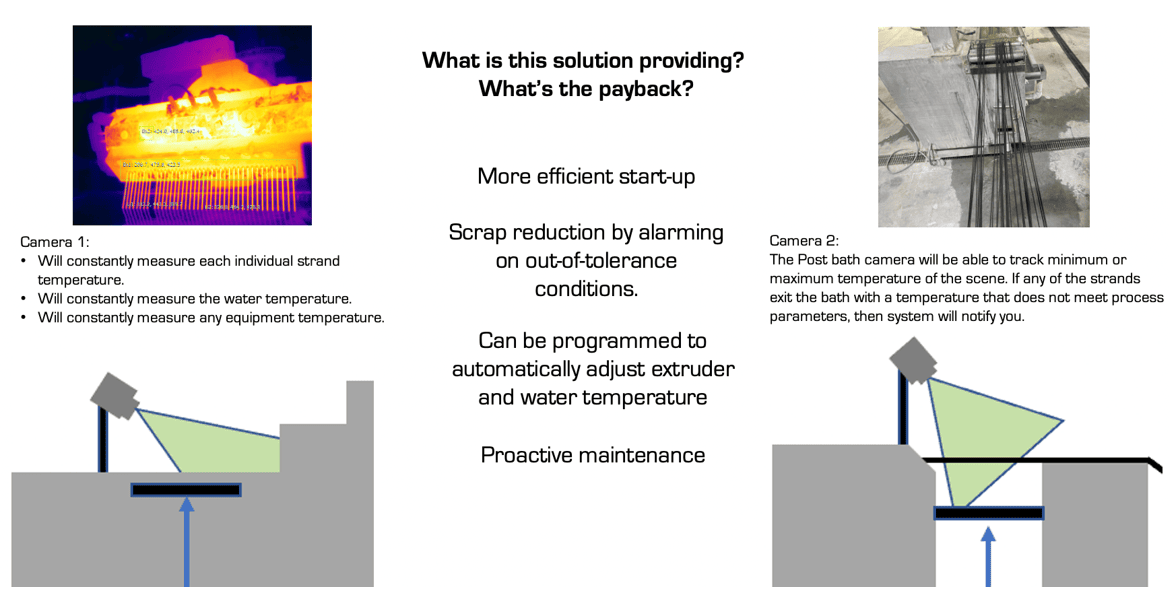

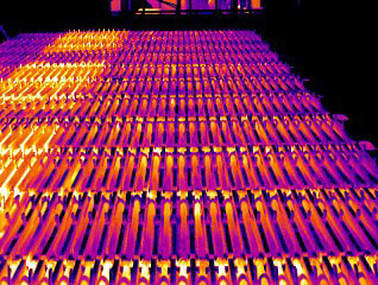

Extrusion Monitoring Solution

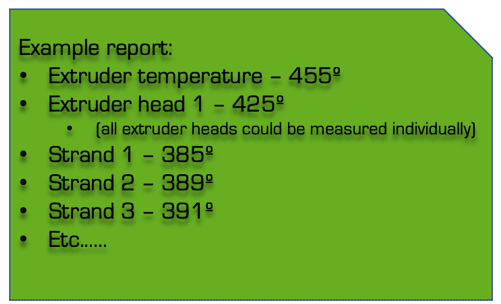

All data (thermal image and temperature) are stored in the system ready to send directly to your inbox.