What is thermal energy?

How can we use it to benefit your company?

Thermal energy is the total of all kinetic energies within a given system. This includes vibrational, translational, and rotational. These energies are present everywhere in the world. We can view these energies with a thermal camera, and use them to monitor the heat and stability of an industrial component, maximize efficiency in an automated assembly line, and maintain asset protection in warehouses. Welding plastics can be very messy, and inaccurate. With infrared emitters, we can reduce the welding time and increase efficiency of the automated or manual welding process.

How thermal cameras can maintain the integrity of your equipment

The average factory is constantly working, day and night. This means that the equipment and machines are running nonstop, causing an increase in heat, which can cause plenty of issues like structural failure, and can reduce the hull integrity of the machine. When a machine breaks down, it can stop all work in that field, and cause loss of efficiency and increase production times. Infrared cameras can detect the hot-spots in the machine and prevent failure and overexertion. Newer equipment is being used in the work place every day, which costs money to maintain. Infrared cameras can give you the asset protection you need to continue producing your products.

–How it was first discovered

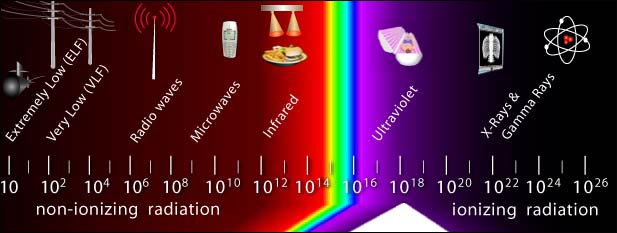

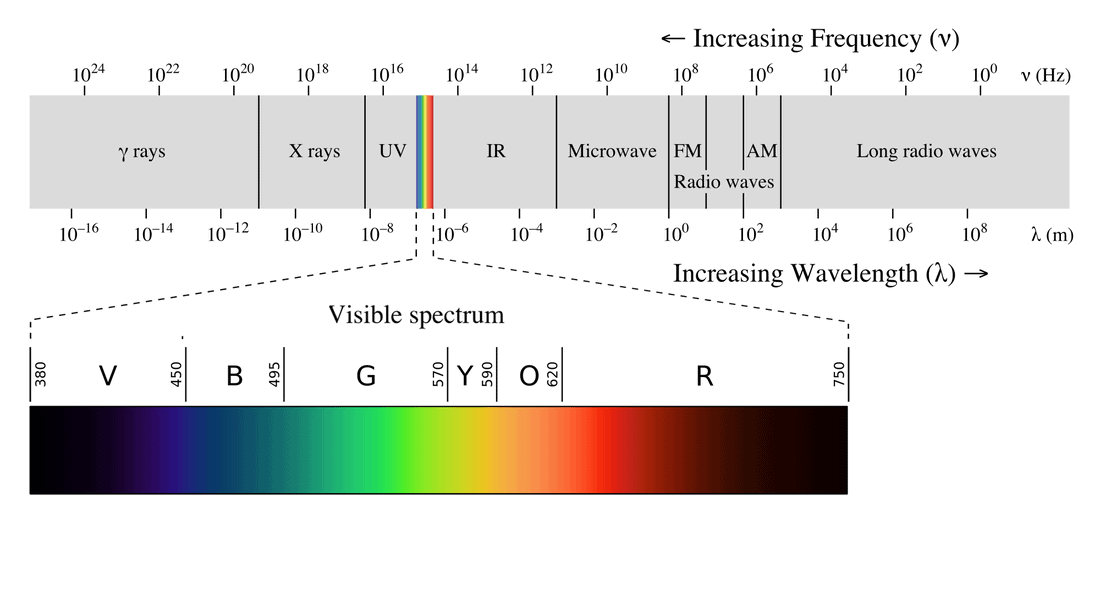

-Infrared was discovered in 1800 by Sir William Herschel as a form of radiation beyond red light. These “infrared rays” (infra is the Latin prefix for “below”) were used mainly for thermal measurement. There are four basic laws of IR radiation: Kirchhoff’s law of thermal radiation, Stefan-Boltzmann law, Planck’s law, and Wien’s displacement law. The development of detectors was mainly focused on the use of thermometer and bolometers until World War I. A significant step in the development of detectors occurred in 1829, when Leopoldo Nobili, using the Seebeck effect, created the first known thermocouple, fabricating an improved thermometer, a crude thermopile. He described this instrument to Macedonio Melloni. Initially, they jointly developed a greatly improved instrument. Subsequently, Melloni worked alone, developing an instrument in 1833 (a multielement thermopile) that could detect a person 10 meters away. The next significant step in improving detectors was the bolometer, invented in 1880 by Samuel Pierpont Langley. Langley and his assistant Charles Greeley Abbot continued to make improvements in this instrument. By 1901, it had the capability to detect radiation from a cow from 400 meters away, and was sensitive to differences in temperature of one hundred thousandths of a degree Celsius

(Wikipedia – REWORD IN OWN WORDS)

–How the first camera was created

In 1929, Hungarian physicist Kálmán Tihanyi invented the infrared-sensitive (night vision) electronic television camera for anti-aircraft defense in Britain. Years later, in 1947, the United States invented the first infrared line scanner. While it was a massive advancement in technology,

-took nearly an hour to develop a single image in infrared back in 1947

-The first infrared linescan system was the British Yellow Duckling of the mid-1950s.

—-Used a continuously rotating mirror and detection system.

-This work was further developed at the Royal Signals and Radar Establishment in the UK when they discovered mercury cadmium telluride could be used as a conductor that required much less cooling.

-Honeywell in the United States also developed arrays of detectors which could cool at a lower temperature, but they scanned mechanically.

-In 1969 Michael Francis Tompsett at English Electric Valve Company in the UK patented a camera which scanned pyro-electronically and which reached a high level of performance after several other breakthroughs throughout the 1970s. Tompsett also proposed an idea for solid-state thermal-imaging arrays, which eventually led to modern hybridized single-crystal-slice imaging devices