Infrared Emitters / Heaters

Welcome to Emitted Energy Corporation, your premier source for advanced infrared heating solutions. We specialize in designing and manufacturing state-of-the-art infrared emitters that set industry standards for precision, efficiency, and adaptability.

Emitter Styles

What is Infrared Technology?

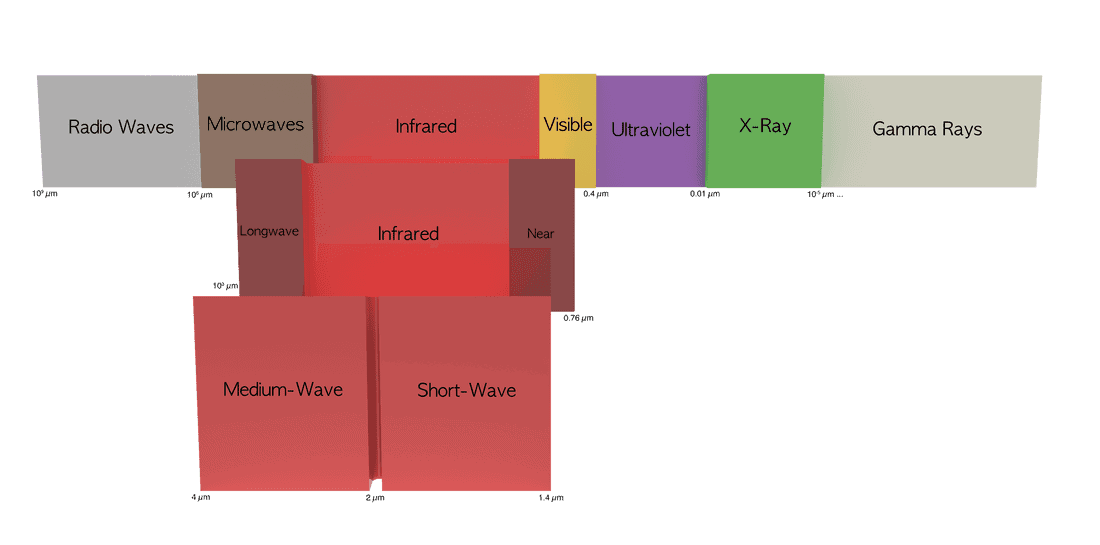

Infrared radiation is a form of electromagnetic energy emitted by atoms and molecules in all objects with temperatures above absolute zero (-273°C). Infrared (“below” or “beyond” red) lies between the visible and microwave spectrum. When infrared waves encounter an object, they can reflect, diffract, refract, transmit, or be absorbed, often simultaneously. Invisible to humans, infrared starts at 0.76 microns, extending to 10.0 microns. All objects emit infrared energy based on their temperature..

Key Features

At Emitted Energy Corporation, we offer a range of innovative features and capabilities:

Standardization

Emitted Energy provides a suite of standard configured emitters to fit a variety of applications. Build a lamp from our configuration worksheet to get started.

Customization

Emitted Energy Corporation’s infrared emitters can be fully customized to meet specific customer requirements. This ensures optimal shape following, temperature control and thermal distribution tailored to individual industrial processes.

Variety of Wavelengths

We offer a broad range of infrared emitters, including:

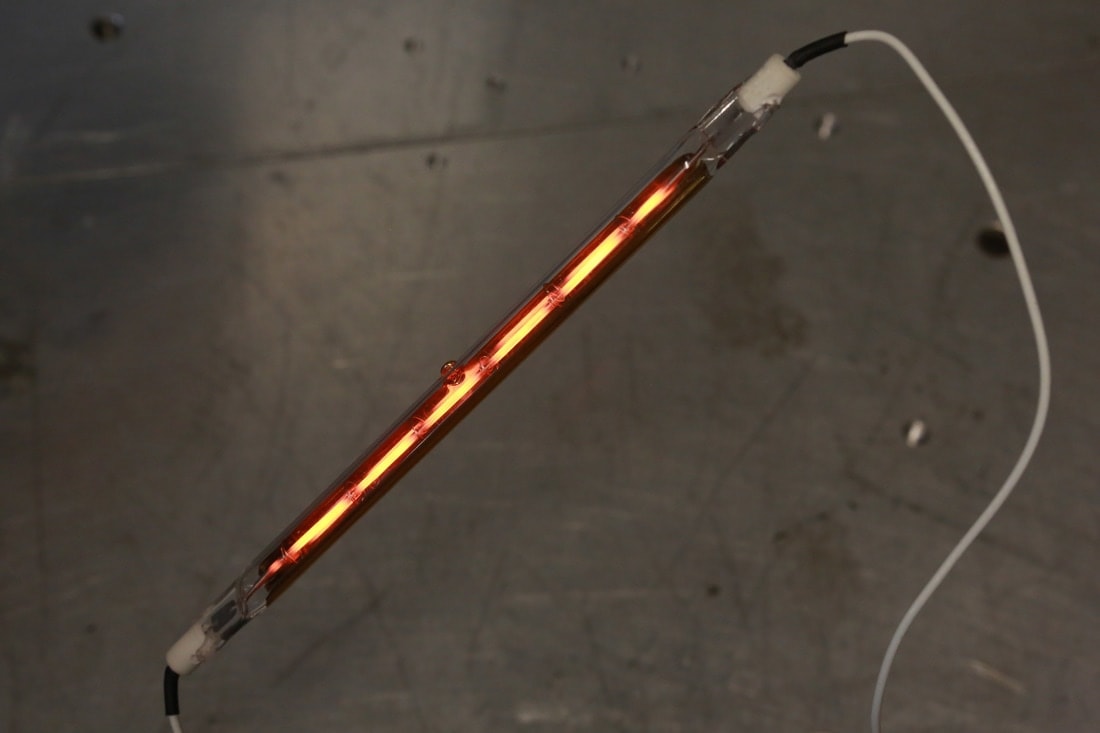

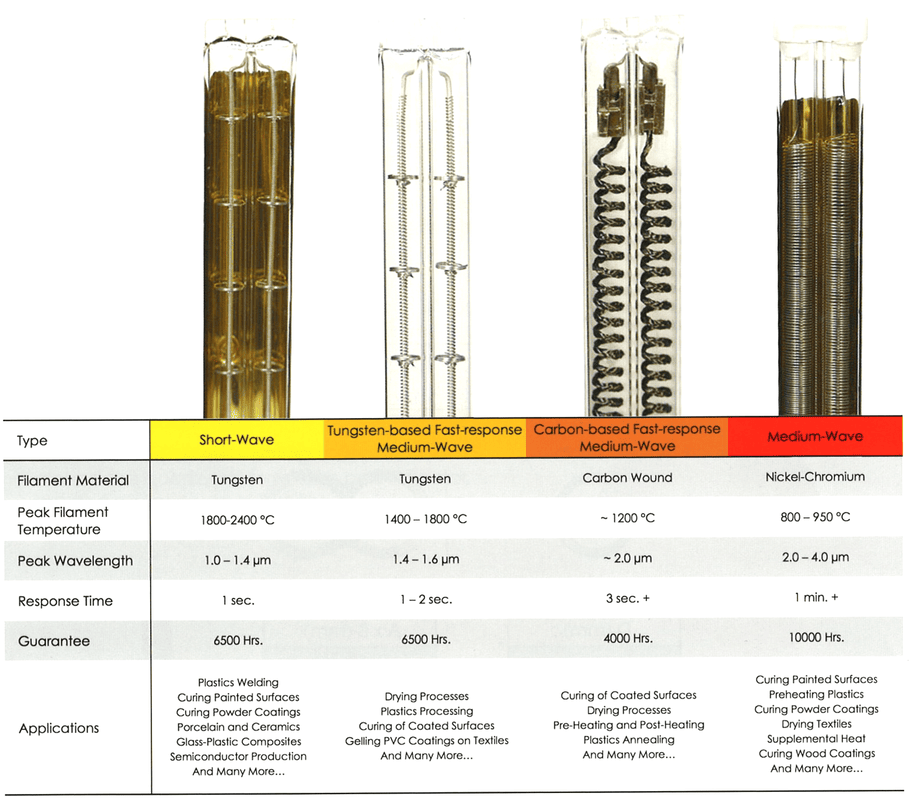

Short-Wave Emitters

Ideal for applications requiring intense heat and immediate response.

Short-Wave Infrared Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Tungsten

- Filament Temperature: 1800 – 2400°C (3300 – 4400°F)

- Peak Wavelength: 1.0 – 1.4 µm

- Response Time: About 1 sec.

- Typical Applications: – Plastics Welding

– Curing Painted Surfaces

– Curing Powder Coatings

– Polymerization of coatings for cooking utensils

– Drying porcelain and ceramics

– Drying and production of glass-plastic composites

– Semiconductor Production

Fast-Response Medium-Wave Emitters

Suitable for processes needing rapid temperature adjustments.

Fast-Response Medium-Wave Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Tungsten

- Filament Temperature: 1400 – 1800°C (2500 – 3300°F)

- Peak Wavelength: 1.4 – 1.6 µm

- Response Time: 1 – 2 sec.

- Typical Applications: – Drying Processes

– Plastics Processing

– Curing of Coated Surfaces

– Gelling PVC coatings on textiles

– And Many Others…

Carbon-Based Medium-Wave Emitters

Perfect for applications that require precise thermal profiles.

Carbon-based Medium-Wave Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Wound Carbon Fiber-Woven

- Filament Temperature: ~ 1200°C (~ 2200°F)

- Peak Wavelength: ~ 2.0 µm

- Response Time: > 3 sec.

- Typical Applications: – Drying Processes

– Curing of Coated Surfaces

– Pre-heating and Post-heating

– And Many Others…

Medium-Wave Emitters

Versatile solutions for various industrial heating needs.

Medium-Wave Infrared Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Nickel-Chromium Alloy

- Filament Temperature: 800 – 950°C (1500 – 1800°F)

- Peak Wavelength: 2.0 – 4.0 µm

- Response Time: > 1 min.

- Typical Applications: – Curing Painted Surfaces

– Preheating Plastics

– Curing Powder Coatings

– Drying / heat setting textiles after dyeing or printing

– Supplemental heating

– Drying or inks for printing and silk-screening

– Preheating and curing wood coatings

– Glass Curing

– And Many Others

Efficient Heating

Our infrared emitters deliver efficient heating, enhancing product quality and operational efficiency across diverse industries.

Integration with Thermal Cameras

When integrated with our advanced thermal cameras, these emitters facilitate Infrared Machine Vision, Process Control, and Quality Assurance Imaging. This combination helps identify inefficiencies and thermal anomalies, ensuring optimal process performance.

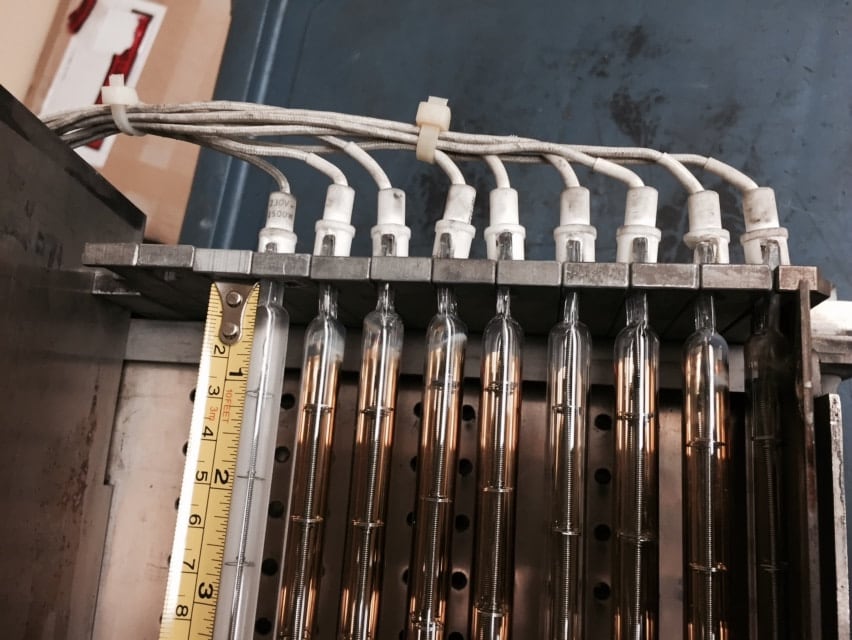

Heater Banks

Emitted Energy Corporation also provides heater banks, offering a cost-effective solution for incorporating infrared heat into industrial processes. These banks simplify the adoption of infrared technology, improving efficiency and product quality.

Precision and Control

Our emitters are engineered for precision and control, which are essential for maintaining high standards of product quality and operational efficiency.

Integration with PLCs

When coupled with phase-angle power controllers such as, (Link), the emitter can be controlled directly through a PLC and seamlessly integrated into a heating process, enabling automated power adjustments, optimal temperature control, and process efficiency.

Real-Time Monitoring

Leveraging thermal imaging technology to enable real-time monitoring and tracking of temperature changes. This provides valuable data-driven insights into process control, performance, and optimization.

Expert Support

Emitted Energy Corporation offers expert support to assist in selecting and integrating the right infrared emitters into your processes, ensuring optimal performance and efficiency.

Primary Applications

Our infrared emitters are pivotal in several industrial applications:

- Industrial Heating: Ensuring precise heat control crucial for maintaining product quality and efficiency.

- Manufacturing Processes: Used in various manufacturing processes to ensure controlled heating.

- Space Heating: Effective in processes like space heating, powder curing, and glass manufacturing.

- Process Monitoring: Through our Thermal Process Monitoring System (TPMS), offering comprehensive monitoring and preventing process failures.

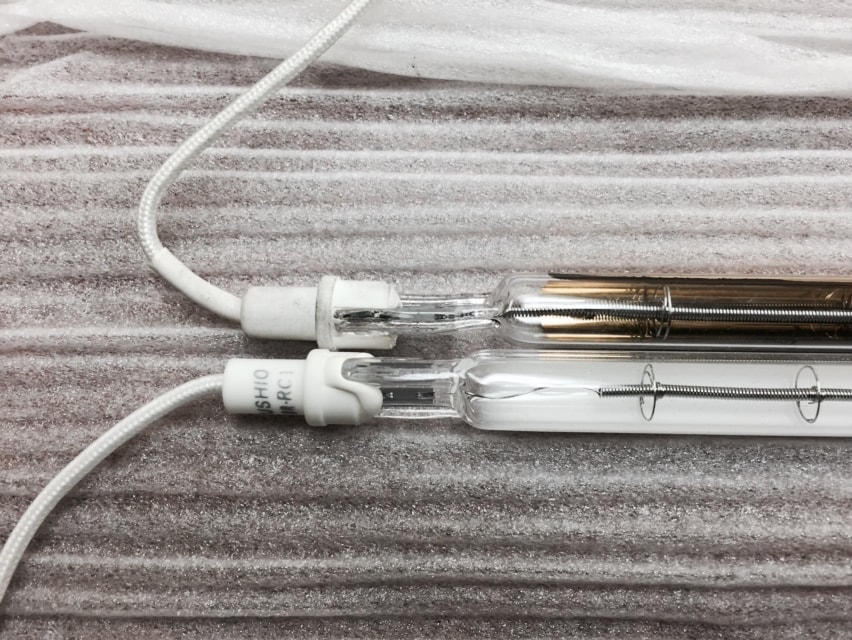

Industrial Heating Solutions with Emitted Energy Corporation

Emitted Energy Corporation’s infrared emitters are one of the leading industrial heating technologies. With customization options, a variety of wavelengths, efficient heating capabilities, and integrated safety features, our emitters meet the most demanding industrial requirements. Supported by expert guidance, our infrared emitters not only enhance operational efficiency but also elevate product quality, positioning your business for success in an increasingly competitive market. Get in touch with us today to learn more about our infrared emitters, including twin tube infrared emitters and single infrared emitter options.