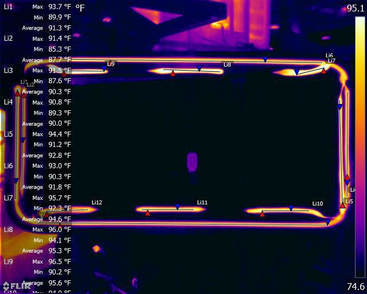

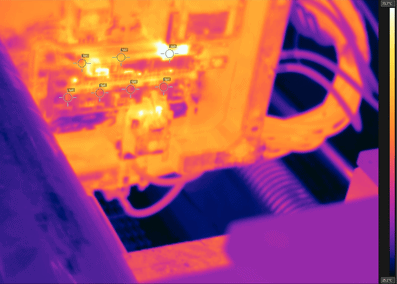

Travel TPMS

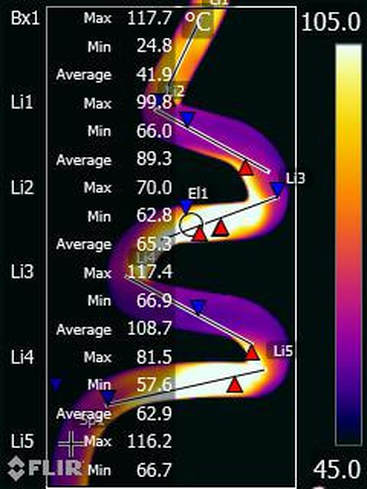

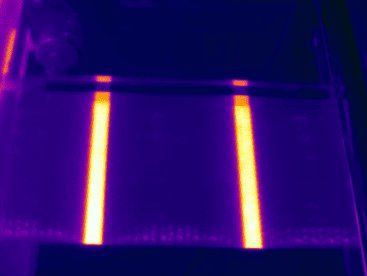

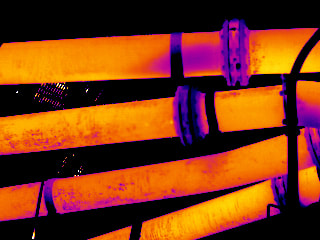

The Travel TPMS gives you great flexibility for when you just want check out thermal imaging with your current processes. Get a camera and a laptop out on your floor!

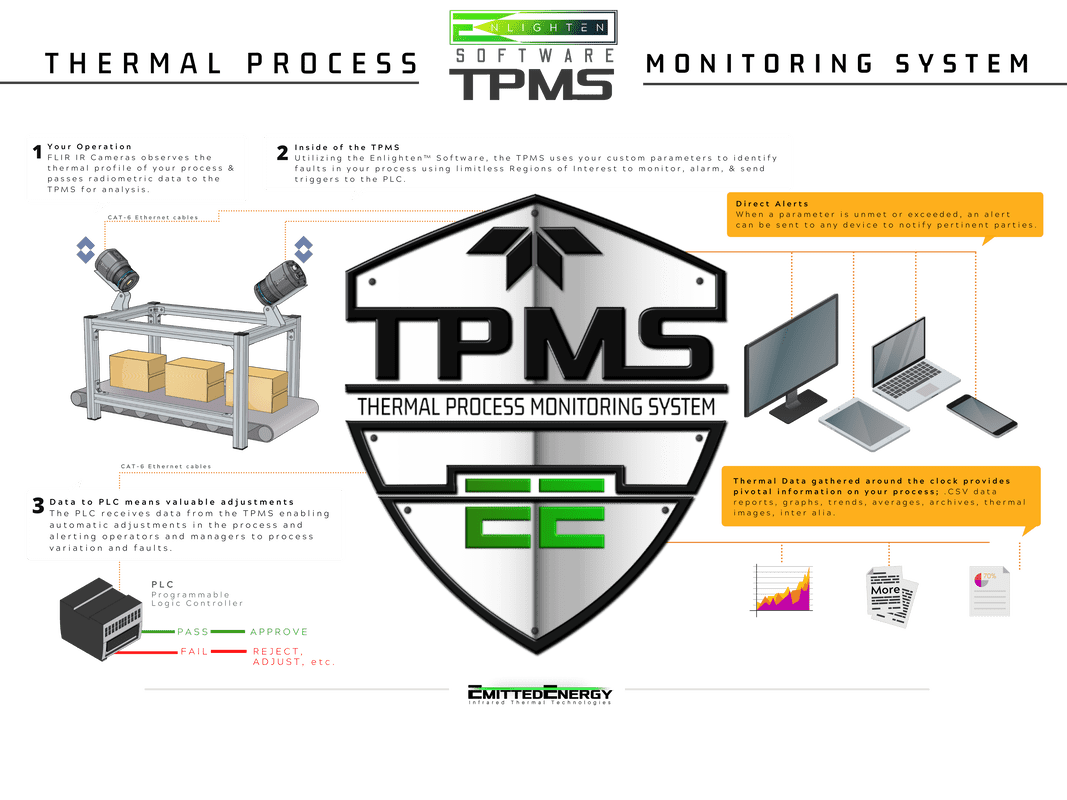

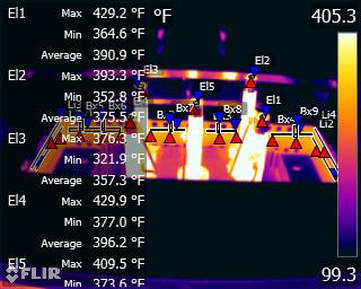

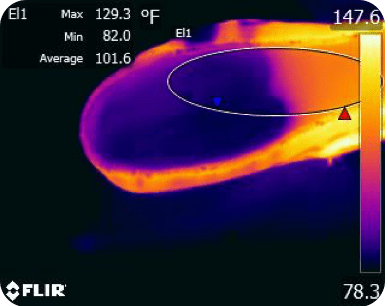

Versatile TPMS

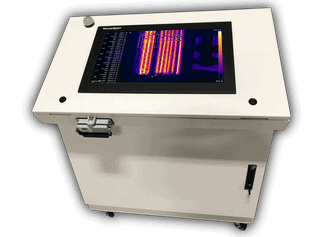

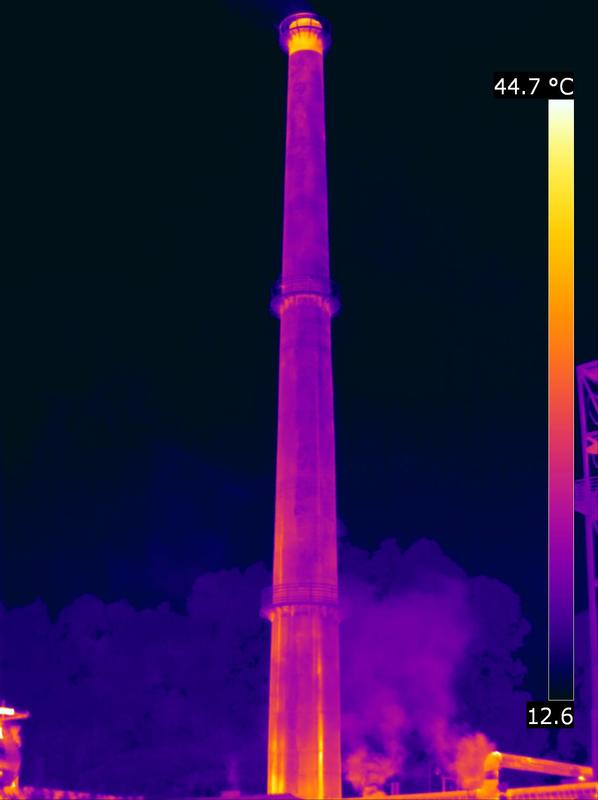

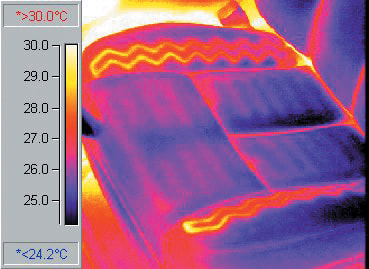

The Versatile TPMS provides the best of both worlds from the Travel and the Integrated systems. Get a high-performance software package that you can bring around to multiple pieces of equipment.

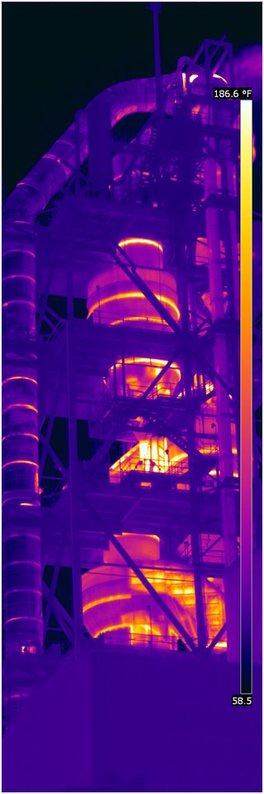

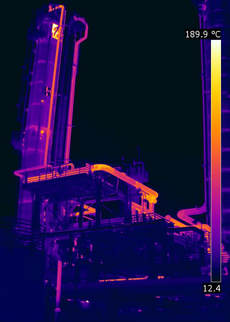

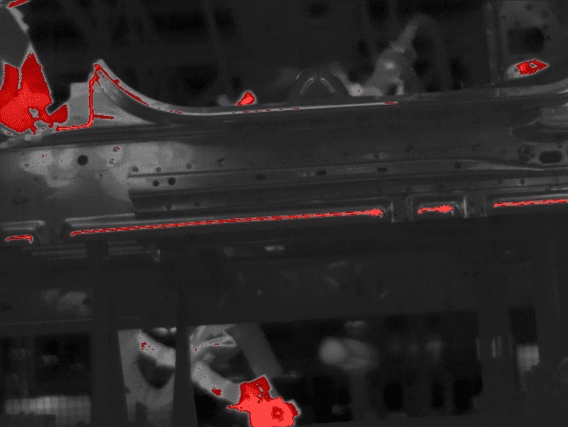

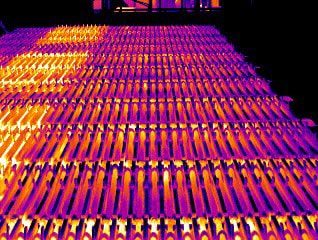

Integrated TPMS

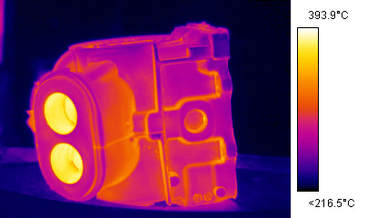

For a fully integrated system, go with the Integrated TPMS. Add a seamless thermal camera system to your existing or new equipment for complete process monitoring and control.