Infrared Emitters / Heaters

Benefits of Infrared Heating by Emitted Energy

- Decrease power consumption and increase your process speed

- Non-Contact Heating

- Precisely adjust applied heat based on your material properties

- Precision heating with infinite controllability

- Instant on and off response times

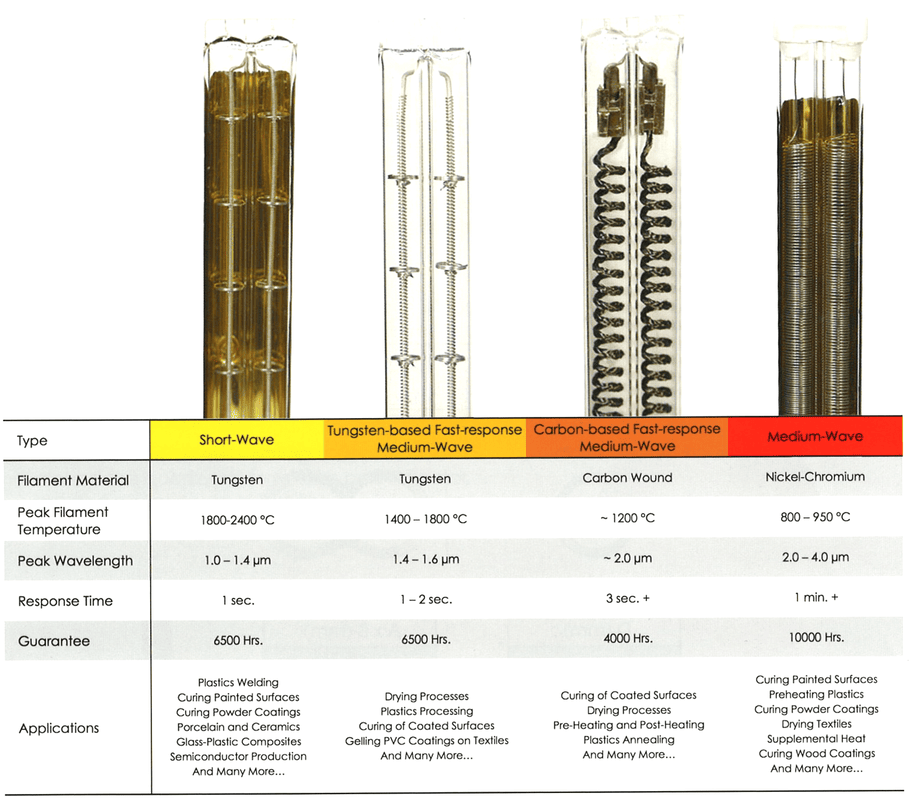

Emitted Energy Corporation manufactures Short-Wave, Fast-Response Medium-Wave, Carbon-based Medium-Wave and Medium-Wave infrared emitters. Each with the ability to be completely customized to your specifications, allow us to help you make the right selection to fit your needs.

Emitter Styles

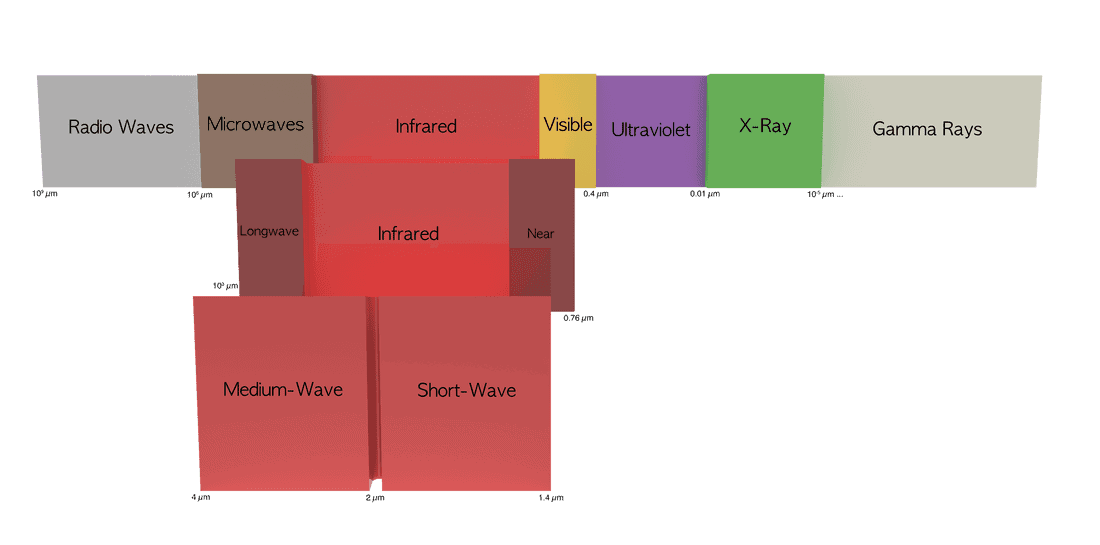

What is Infrared Technology?

Infrared radiation is a form of electromagnetic energy that is generated by the vibration and rotation of atoms and molecules within all objects with temperatures above absolute zero (0° Kelvin; -459° F; or -273° C). Infrared (literally meaning “below” or “beyond” the red) is located between the visible and microwave portions of the electromagnetic spectrum and shares many of the same properties of visible light, except it has a longer wavelength. When infrared waves encounter a solid object they can be reflected (bounce off), diffracted (scattered), refracted (bent), transmitted (pass through), or absorbed by the object where several of these effects can take place at the same time. The visible portion of the spectrum ranges in wavelength from 0.38 microns to 0.76 microns. The infrared portion, which is not visible to the human eye, begins at 0.76 microns and extends to 10.0 microns (micron = one thousandth of a millimeter, one millionth of a kilometer). All objects emit infrared as a function of their temperature.

Infrared Heaters by Emitted Energy

Short-Wave Infrared Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Tungsten

- Filament Temperature: 1800 – 2400°C (3300 – 4400°F)

- Peak Wavelength: 1.0 – 1.4 µm

- Response Time: About 1 sec.

- Typical Applications: – Plastics Welding

– Curing Painted Surfaces

– Curing Powder Coatings

– Polymerization of coatings for cooking utensils

– Drying porcelain and ceramics

– Drying and production of glass-plastic composites

– Semiconductor Production

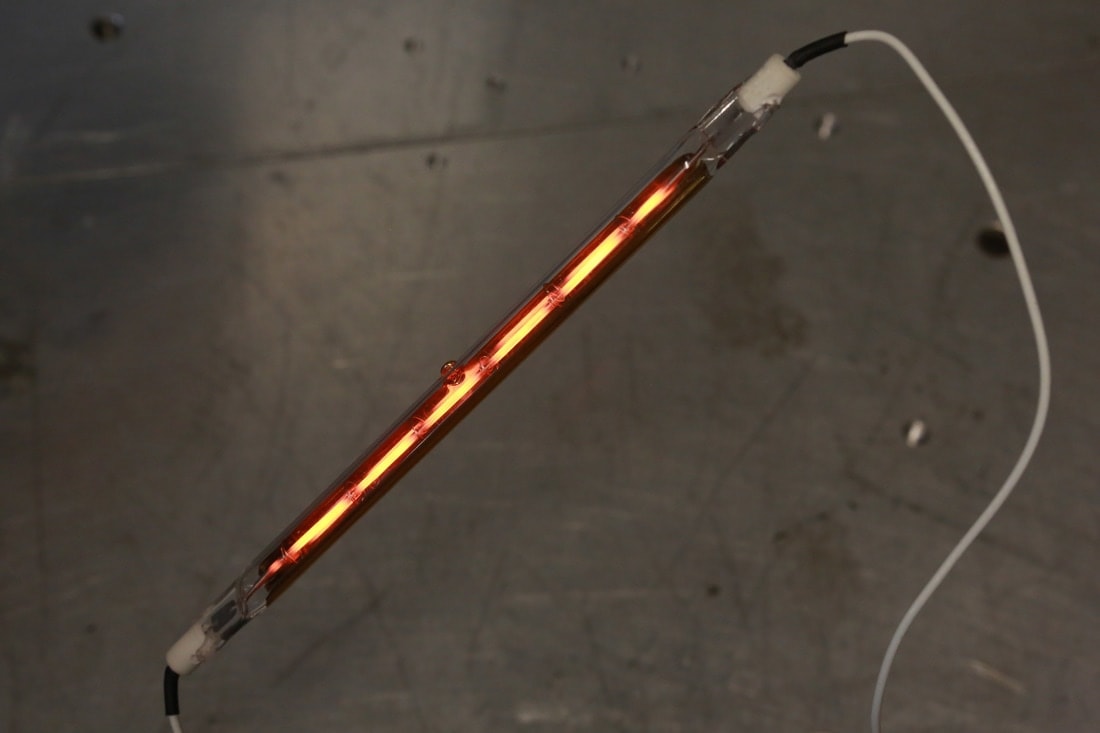

Short-Wave Infrared Heaters

Short-wave infrared emitters utilize a low-mass tungsten filament that is incased in a special blend of inert gasses. This provides a very high energy source capable of responding instantly to voltage changes, allowing for precise temperature control for a variety of applications.

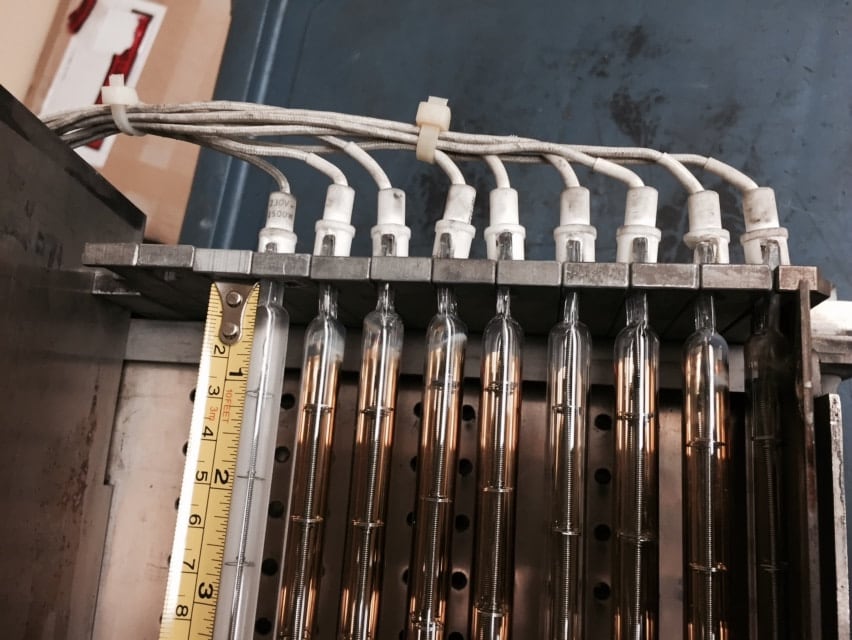

Fast-Response Medium-Wave Heaters

Fast-Response Medium-Wave infrared emitters are heaters that fall between the short and medium-wave standards. Utilizing the best of both worlds, fast-response medium-wave emitters are capable of almost instant response times while hitting a larger wavelength of the electromagnetic spectrum.

Fast-Response Medium-Wave Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Tungsten

- Filament Temperature: 1400 – 1800°C (2500 – 3300°F)

- Peak Wavelength: 1.4 – 1.6 µm

- Response Time: 1 – 2 sec.

- Typical Applications: – Drying Processes

– Plastics Processing

– Curing of Coated Surfaces

– Gelling PVC coatings on textiles

– And Many Others…

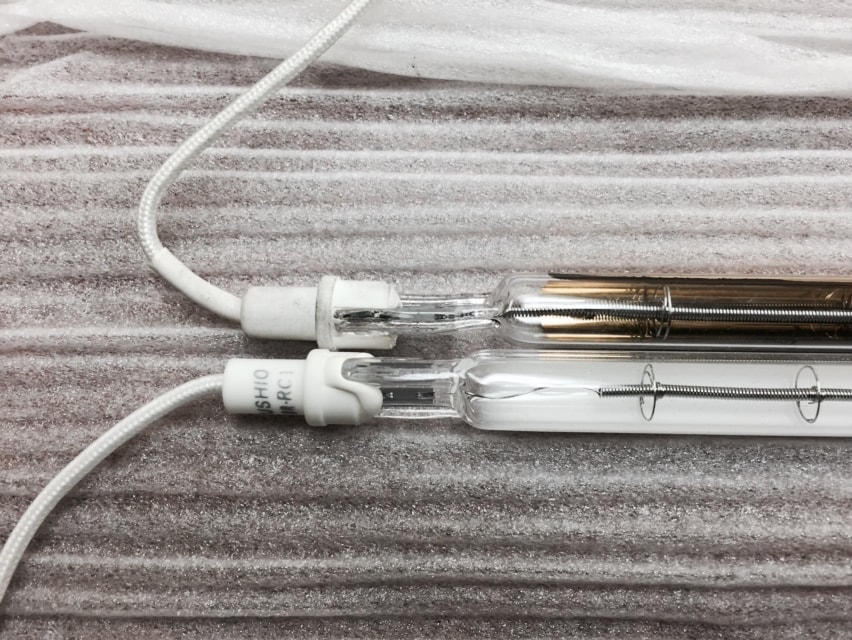

Carbon-based Medium-Wave Heaters

Emitted Energy Carbon-based Medium-Wave Infrared Emitters are heaters that utilize a wound fiber-woven carbon filament. This unique lamp is ideal for drying applications that don’t require high, intense heat of short-wave and long drawn-out heat of medium-wave, but rather falls in between. Note: only available with white ceramic reflector coating.

Carbon-based Medium-Wave Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Wound Carbon Fiber-Woven

- Filament Temperature: ~ 1200°C (~ 2200°F)

- Peak Wavelength: ~ 2.0 µm

- Response Time: > 3 sec.

- Typical Applications: – Drying Processes

– Curing of Coated Surfaces

– Pre-heating and Post-heating

– And Many Others…

Medium-Wave Infrared Heaters

Emitted Energy Medium-wave infrared emitters utilize a high temperature nickel/chromium alloy filament to provide a steady source of heat. These high efficiency emitters convert 80 to 90 percent of the input electrical energy into infrared radiation making it ideal for situations requiring longer applications of heat.

Medium-Wave Infrared Heaters Learn more

- Glass Tube: 99.9% Pure Fused Silica Quartz Sealed

- Filament Material: Nickel-Chromium Alloy

- Filament Temperature: 800 – 950°C (1500 – 1800°F)

- Peak Wavelength: 2.0 – 4.0 µm

- Response Time: > 1 min.

- Typical Applications: – Curing Painted Surfaces

– Preheating Plastics

– Curing Powder Coatings

– Drying / heat setting textiles after dyeing or printing

– Supplemental heating

– Drying or inks for printing and silk-screening

– Preheating and curing wood coatings

– Glass Curing

– And Many Others