Plastic Joining

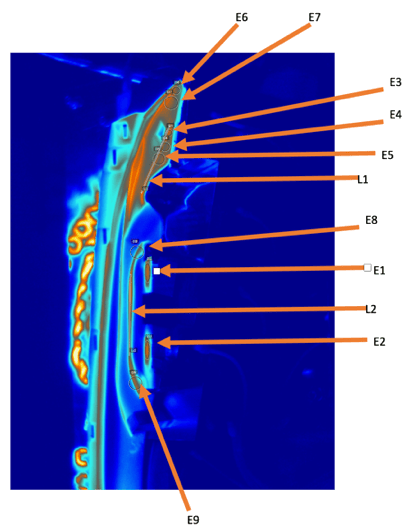

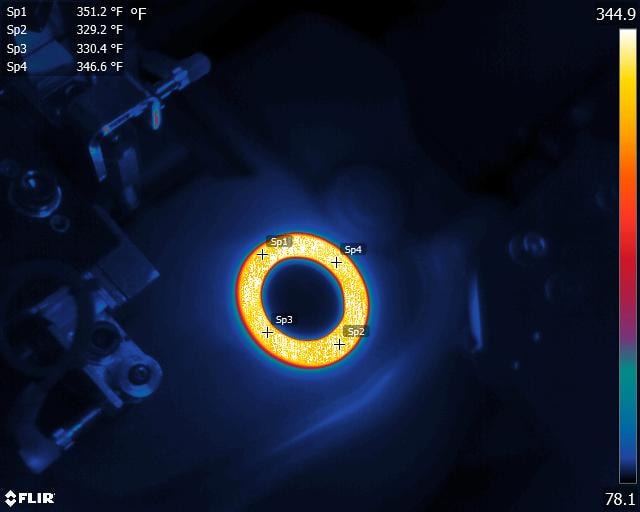

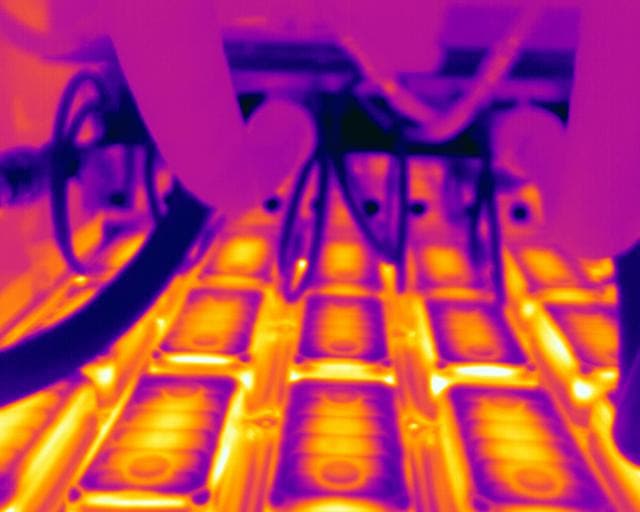

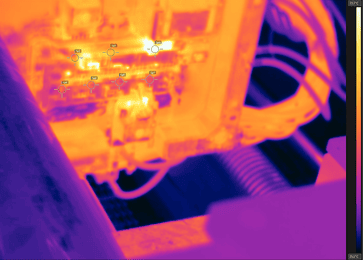

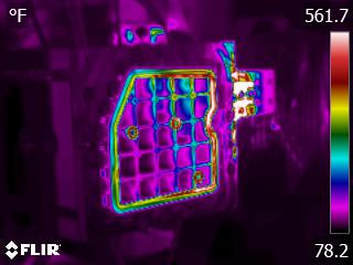

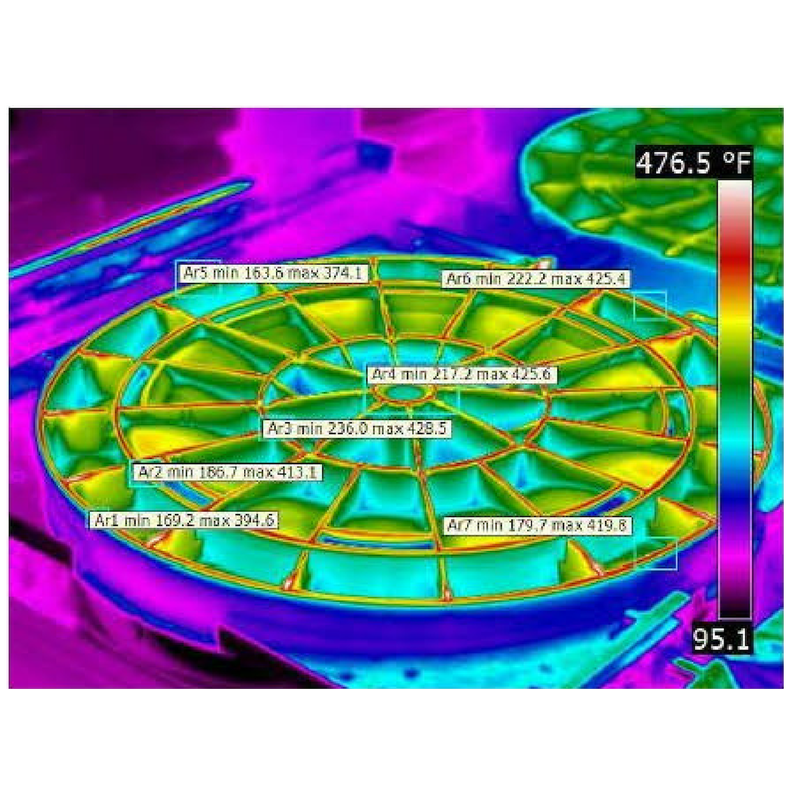

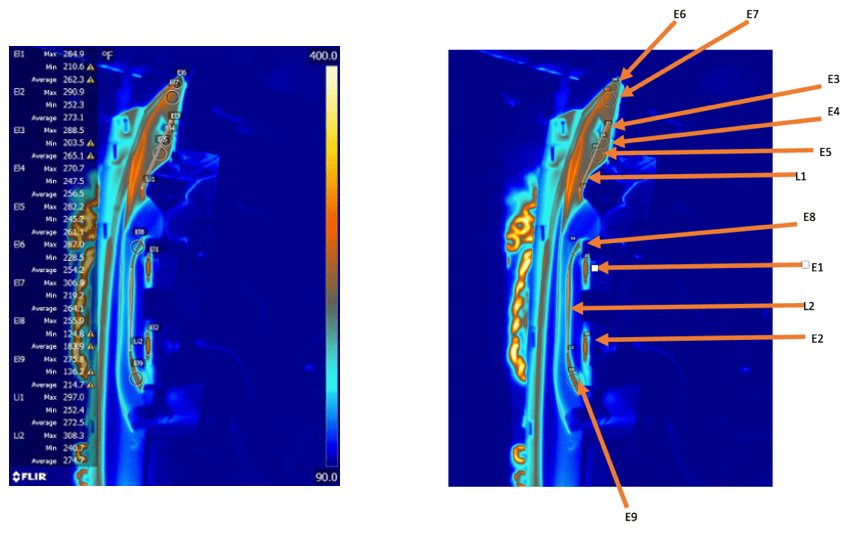

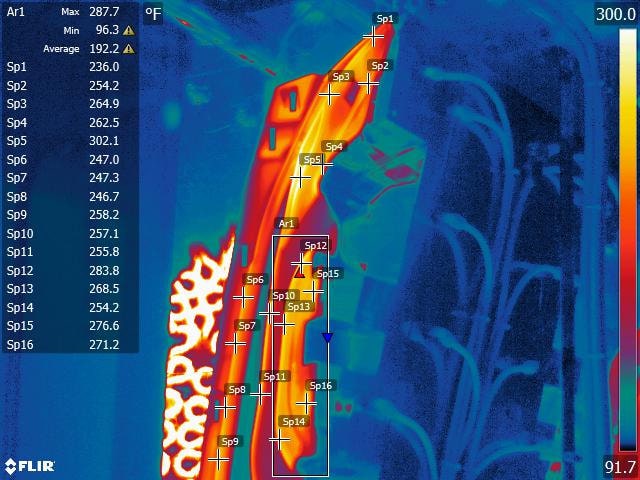

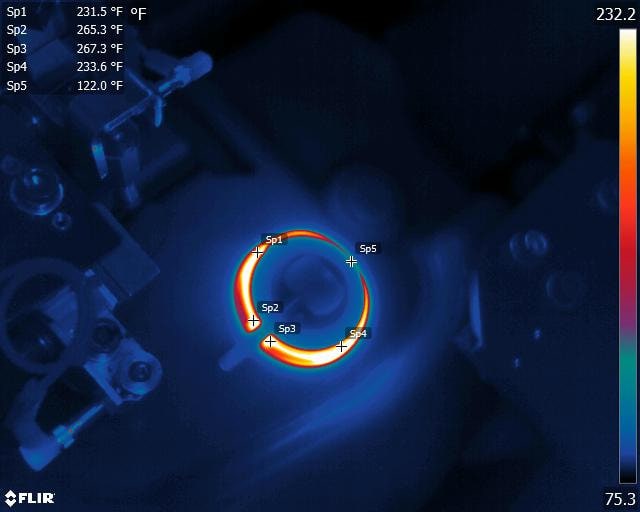

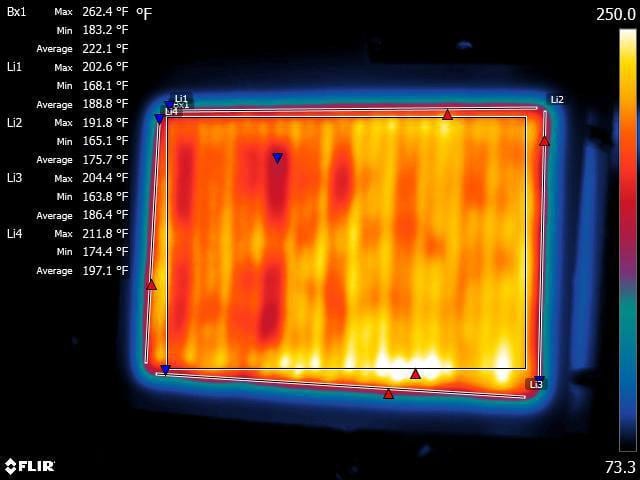

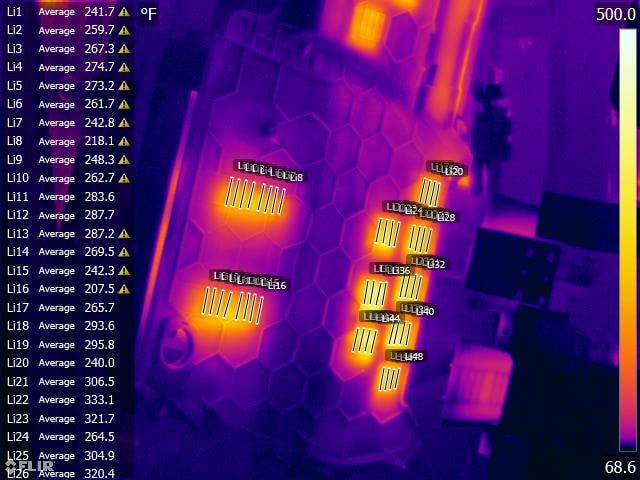

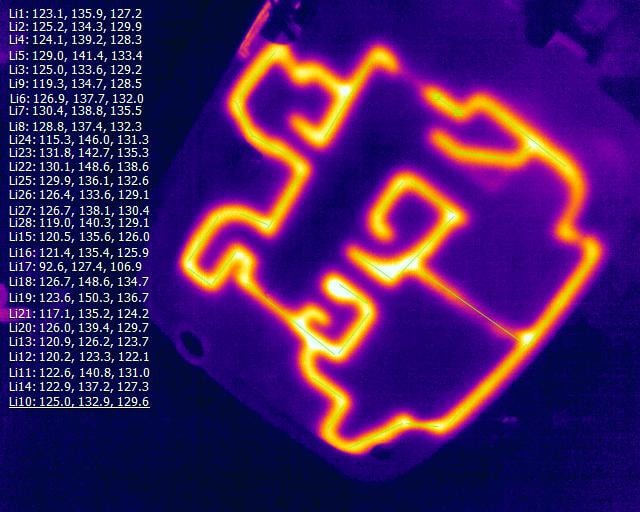

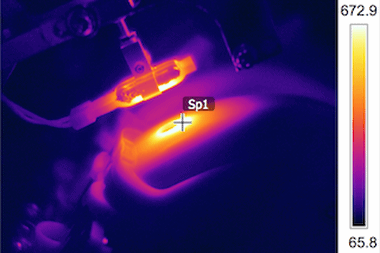

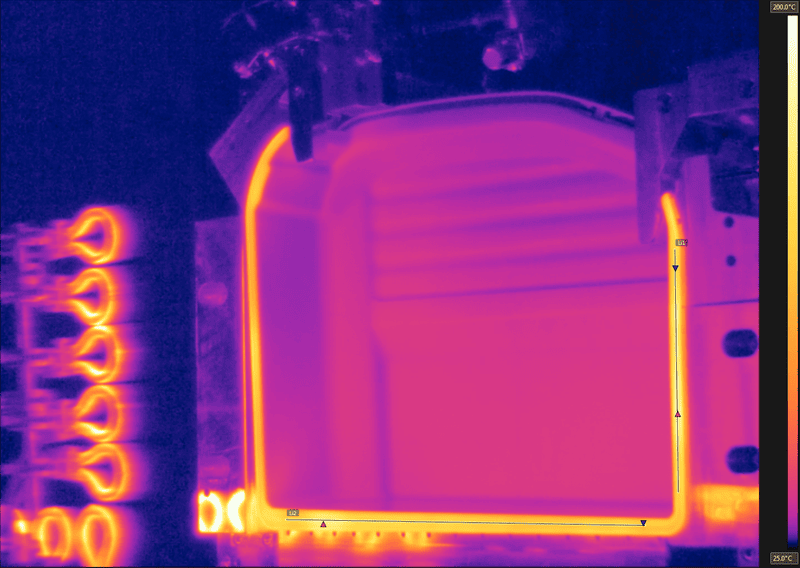

Thermal imaging can solve complex problems typically not seen by the naked eye, such as defects in the different plastic joining processes available. Spotting potential issues in the finished product will ensure consistency and the highest quality standards. At Emitted Energy Corporation, we provide clear solutions with our equipment and services to effectively detect these flaws.

What is Plastic Joining?

Plastic joining is a method where semi-finished plastic components are joined together or with other elements. It can be a fabrication method or a type of damage repair. Our plastic joining solution focuses on plastic welding technologies such as infrared, laser, vibration and ultrasonic welding, hot plate welding, and induction welding. There are three primary methods for the plastic joining process. These include:

- Welding: The process of joining two faces using heat and/or pressure. This can include; infrared welding, laser welding, vibration welding, ultrasonic welding, or hotplate welding.

- Mechanical fastening: Refers to using latches, hinges, or snap fits into the design, offering easier disassembly. However, finished products are susceptible to stress concentrations and corrosion.

- Adhesive bonding: Utilizes a substance to create a bond between two materials. Some problems may occur, such as difficulty bonding the materials with adhesives and the long curing time.

Each method has challenges, and a slight error in the production process can lead to undetected or undiagnosed issues. Thermal imaging can help detect these issues before reaching the customer to ensure the product has no defect.

Thermal Imaging Solutions by Emitted Energy Corporation

At Emitted Energy Corporation, we provide a compelling solution to unseen problems and challenges in our customer’s products. It’s a form of quality control that businesses should apply in their overall operations, especially for plastic joining processes.

Other benefits of employing our thermal imaging solutions:

- Provides a complete picture of the plastic joining process and real-time feedback on its temperature distribution. The picture is an image of the outputted product of the process which contains critical data and is otherwise unobservable when only registering the process inputs.

- Corrects the problem in real time by adjusting its temperature and other process parameters.

- Eliminates the need for manual adjustments and intervention.

- Cost-effective and saves time due to its high efficiency.

- Allows you to improve the consistency and quality of your products.

Our products are equipped with the latest technology to aid in the plastic joining process and help you achieve the best results.

Your Infrared Thermal Technologies Partner

We strive to increase your product throughput without compromising its quality. With that said, we’ll aid in finding a suitable thermal imaging camera and system that will maximize your production and success.

If precision heat radiation is essential to your manufacturing process, infrared heating technology is a top choice. We consider your project requirements and specifications, ensuring you find the right technology to deliver undeniable results.

See the Difference with Our Thermal Imaging Technology

If plastic joining is a massive part of your manufacturing process, avoid product failure and increase your production rate and profit with reliable thermal imaging technology. At Emitted Energy Corporation, we help customers incorporate this valuable technology into their daily operations for better support.

If you have any questions about our products and services, don’t hesitate to contact us today. Request a quote, and we’ll find a cost-effective and efficient solution.